Measuring a wheel correctly can ensure you get exactly what information you need and speed up the process. If you have calipers that are large enough, that is going to be the best option. If not, a tape measure or ruler can get you close enough. Something also to consider is the manufacturer of the wheel. If it’s a domestic manufacturer, it’s typically imperial measuring, and if foreign, it will be metric measuring.

The first thing to measure is the overall diameter of the wheel. You want to try and measure directly across the wheel, so your measuring device crosses exactly across the center of the wheel. Keep in mind the imperial vs. metric system for this specific measurement. If it’s a wheel that might have some wear to it and you come up with a height just under 8″, most likely it would be an 8″ wheel if it’s a domestic manufacturer.

The first thing to measure is the overall diameter of the wheel. You want to try and measure directly across the wheel, so your measuring device crosses exactly across the center of the wheel. Keep in mind the imperial vs. metric system for this specific measurement. If it’s a wheel that might have some wear to it and you come up with a height just under 8″, most likely it would be an 8″ wheel if it’s a domestic manufacturer.

Next, measure the width of the wheel. You will need to measure the width of the running surface of the wheel and also the width of the hub length. Sometimes the hub length can protrude out past the width of the wheel, or it can recess inside the wheel’s width. Other times it might be different on each side. This is typically one of the hardest measurements to get and more ideal if you have calipers or a way to measure down to the hub. A lot of times, you will need to use your best guess.

From there, you need to determine what bearing you have or what the bore measurement is. Sometimes if it’s a ball bearing or a tapered bearing, you can read the bearing part number on the bearing. If you cannot read the bearing number or it’s a roller bearing, you will need to measure the Inner Diameter (ID) of the bearing along with the Outer Diameter (OD) of the bearing if possible. There could also be a bushing that runs through the bearing. In that case, we will also need to know what that bushing’s OD and ID are. In other cases, there might not be a bearing and we will need to know the wheel’s ID along with any steps that might be in the wheel too, as in the depth and if that ID changes to another size.

Measuring the bolt holes of your caster

Lastly, we need to know the wheel material. It could be a steel wheel, v-groove, flanged, mold on rubber, polyurethane, phenolic, or even nylon. Typically, the color of the wheel doesn’t tell us what material it is unless we know the manufacturer. Then, it could help.

If we have this information, it is typically enough for us to get pointed in the right direction and help you find a replacement for your application.

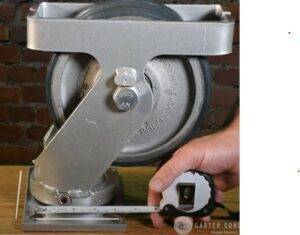

First, start with the bolt holes. You’ll have bolts coming down through the bolt holes, so you’ll want to measure from the center of those bolts, measuring both the width and the leg.

If you don’t have balls coming down, such as if the caster is welded on, or you have something else holding the caster on, then you‘ll want to measure the bolt-hole pattern. You’ll want to measure the inside of the slots and the outside of the slots for the width and length.

The other thing to measure would be the width and length of the overall top plate as well. Once you have those dimensions, the next thing to do would be to measure the overall height. So you’re going to measure from the top of the top plate all the way to the bottom of the wheel. That measurement is going to give you the overall height of the caster.

Next, you’re going to want to measure your wheel diameter and then also the width of the wheel. If it’s a Twergo wheel with three separate wheels, make sure you measure all three discs together to give you that overall width.

After that, you’re going to measure your swivel lead. The swivel lead is the distance from the center of your swivel section to the center of the axle. Try your best to measure that particular distance to figure out what the offset of the wheel is.

This will give you a good baseline of what kind of caster you need. The only next thing would be what kind of wheel material you have on your wheel you tell your caster expert so they can spec the right caster for you.