Most casters have one of three main types of bearings in the wheels. The three main bearings are roller, taper, and ball bearings. However, there are other options for high temperatures, heavy loads, side loading, corrosive resistance, and wet applications. Determining what type of bearing is in your caster depends on the wheel and the axle that is used in the caster.

Ball bearings are maintenance-free and greased for life. If your wheel has a ball bearing, it will have a solid axle and no grease zerk fitting in the wheel. The wheel will roll when it is not under load with minimal effort. Ball bearings provide maximum rolling ease with no maintenance or lubrication required.

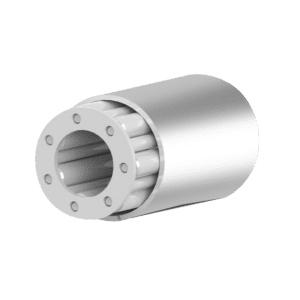

Casters with a roller bearing will either have a hollow axle or a zerk fitting and will have a hardened washer holding them into the wheel. The wheel will roll with minimal effort when it is not under load. The difference between a roller bearing and a ball bearing is that the roller bearings will require maintenance. Roller bearings are capable of carrying a greater load than the same size diameter ball bearing.

Casters with a roller bearing will either have a hollow axle or a zerk fitting and will have a hardened washer holding them into the wheel. The wheel will roll with minimal effort when it is not under load. The difference between a roller bearing and a ball bearing is that the roller bearings will require maintenance. Roller bearings are capable of carrying a greater load than the same size diameter ball bearing.

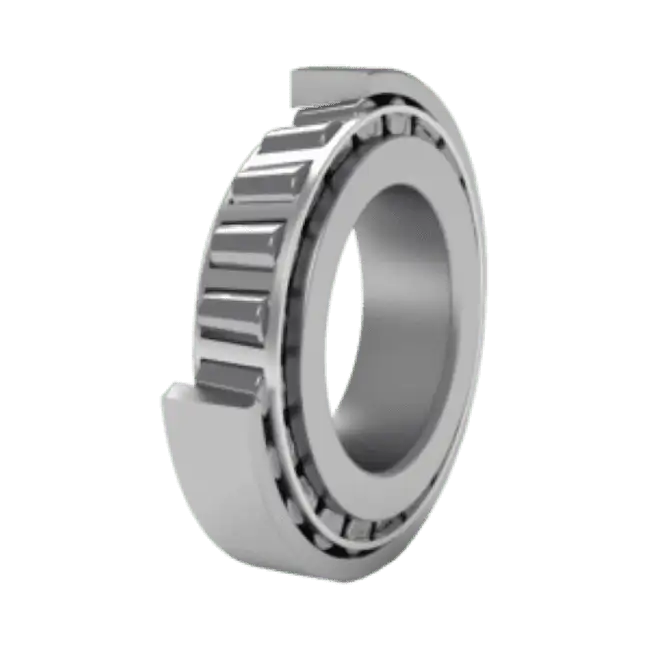

A wheel with a tapered bearing will also require maintenance. Often, the bearings are pre-lubricated prior to installation of the bearings into the wheel. A wheel with taper bearings will either have a hollow axle or a grease zerk in the wheel.

It’s important to check the wheel bearings on a caster during regular upkeep for wear. Here are some general guidelines.

What’s the difference between a tapered bearing and a roller bearing? A tapered bearing must be preloaded before it will roll. This means tapered bearings require effort to roll the wheel when it is not under load. Once the tapered bearings are placed under load, the wheel will roll freely. That’s why taper bearings are typically used for heavier loads. They are also a good choice for applications with excessive side loading and the bearing of choice for high-speed and heavy loads. Whichever the use, taper bearings should be periodically checked for proper adjustment.

The next time you have a caster and are not quite sure what bearing is in the whee,l check for a grease zerk. If the axle or the wheel has a zerk then the caster does not have a ball bearing. The next step is to have the wheel without a load on it. If the wheel moves freely then you have a roller bearing. If the wheel has drag and is hard to spin you have a taper bearing. I hope this helps you to determine what bearing is in your wheel in the caster you have.