Our mission is to provide 100% on-time delivery.

Modular Manufacturing

Modular Manufacturing

Modular manufacturing have relied on Caster Concepts to help improve safety, increase productivity, and solve unique challenges that arise during the production process. This includes heavy duty suspension casters with the strength and stability to move 250,000 lb. modular homes without cracking under pressure, to move these structures easily over a variety of terrains, and with the stability to do it with a lower profile.

- Easier movement of heavy loads over a variety of terrain

- Ergonomic solutions to make moving and maneuvering heavy loads easier

- Durability solutions to extend caster life and reduce wear

Our Well-Built Casters Are Constructed To Outperform, Outlast, And Flat-Out Outclass Anything In The Market.

Remove Choke Points That Slow Down Operations.

Eliminate Constant Caster Replacement Costing Thousands Yearly.

Re-Molding With High-Grade Poly Wheels To Lower Failure Rates, Costs, and Lead Times.

Don't Lower Expectations, Lower Your Total Cost of Ownership.

Removing the Challenges of Moving Modular Manufacturing Through Assembly.

Consider your material handling challenges solved. Caster Concepts’ heavy duty suspension casters have the strength and stability to move 250,000 lb. modular manufacturing over obstacles safely – and repeatedly.

We engineer the best products for the job, and feature products designed to negate the effects of uneven surfaces or debris-filled floors, protecting the loads and making the movement of these heavy structures efficient and easy.

Material handling movement solutions include:

- Quad Wheel 91 Series Skate

- Heavy Duty Spring Loaded Caster

- Custom Caster Solutions

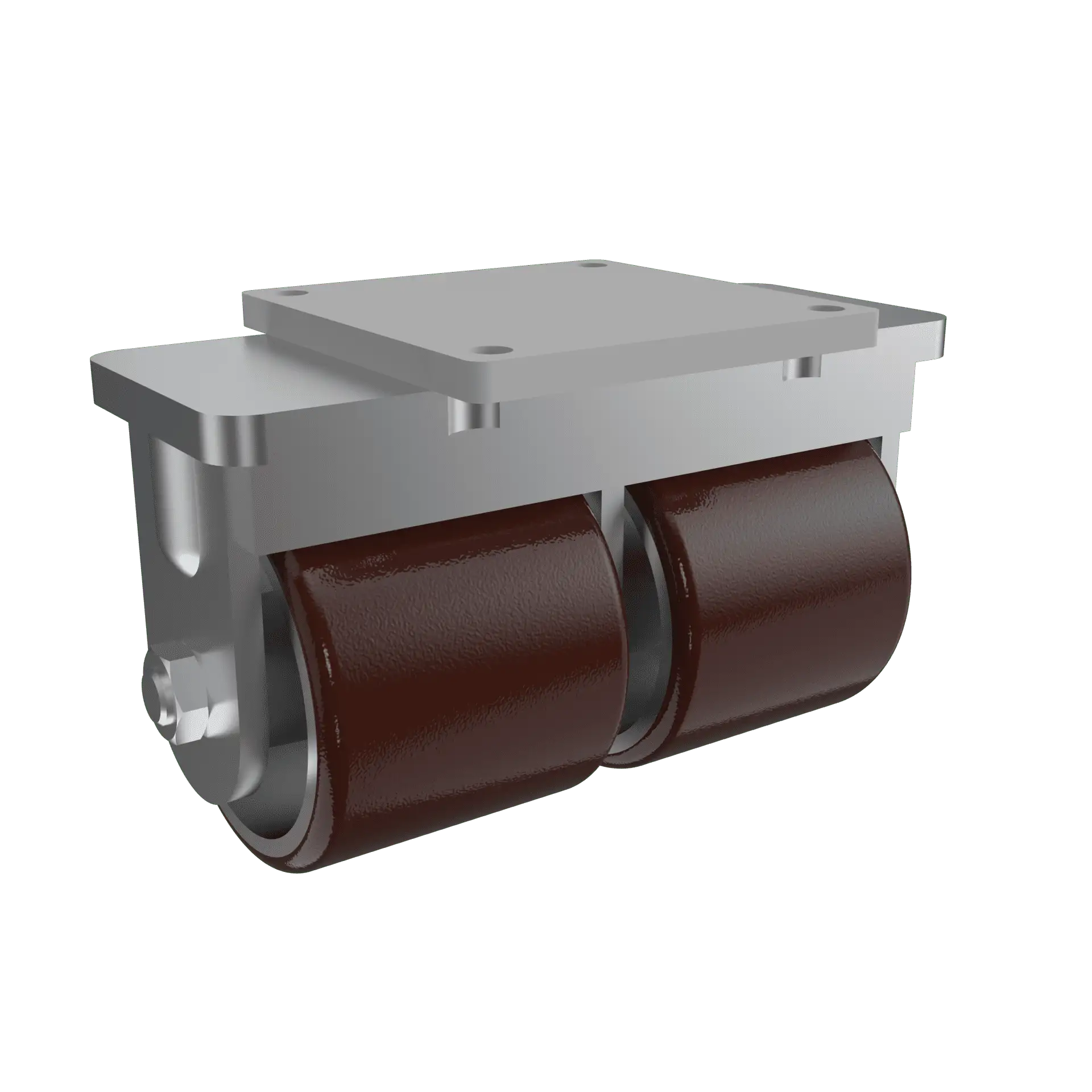

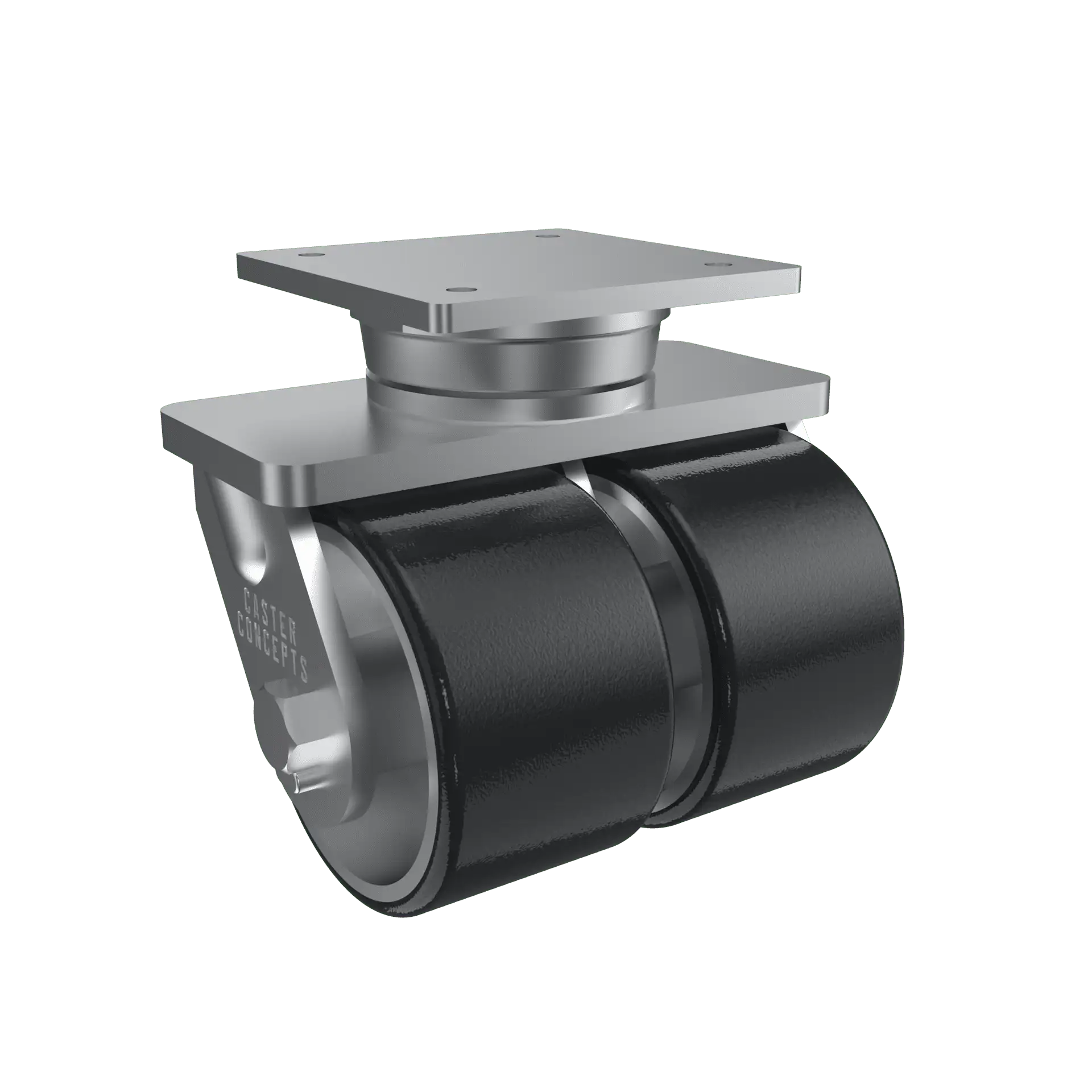

Low Profile Casters With Greater Weight Capacities and Better Stability and Maneuverability.

The heavier load weights and lengths of modular buildings can be hard to maneuver and cause casters to fail, greatly increasing the costs associated with downtime and replacement.

To solve this problem, Caster Concepts’ heavy-duty casters can support large structures without fail and are offered a dual-wheel design to create a lower profile that can carry more weight by spreading the load across a greater surface area.

For extremely heavy loads that are difficult to move manually, motorized solutions are also available that protect against overexertion and make it effortless to move a large structure through a facility.

Low profile and high capacity solutions include:

Explore Expert Solutions for Modular Manufacturing

Eliminating Excessive Downtime Caused by High Failure Rates, High Replacement Costs, and Long Lead Times.

When overseas crane wheels used by a resourcing company didn’t hold up, the result was high caster failure rates and replacement costs, as well as long lead times waiting for the new wheels to come in.

Re-molding the crane wheels with higher-grade polyurethane from Caster Concepts doubled the wheel’s life cycle due to its high tear strength while saving thousands in reduced downtime and caster replacement.

Durability solutions include:

-

- 95A Polyurethane

- T/R 95 Polyurethane Tread features high tear strength for better durability

- Savings of $10,000 every wheel order plus expense and labor for replacement

Build Your Operations With Higher Efficiency.

Recommended Modular Solutions

Quad Wheel 91 Series Skate with Heavy Duty Spring Loaded Caster

- Custom-engineered solution to move 53’ x 18’ buildings weighing 250,000 lbs.

- Eliminated the frequent breakdowns of conventional machine mover skates

- Enabled building to pivot on its center point on uneven ground

81 Series 10,000 lb.Max Kingpinless Caster

- A tough caster built for industrial applications involving shock loading.

- The ease of swiveling leads to long life cycles and lower operation costs.

- Lasted twice as long as previous casters, saving $50,000 annually.

T/R 95 Polyurethane Tread

- Higher tear resistance and greater strength for extended wear

- Maintains higher hardness and elasticity for better ergonomics

Proven Performance in Action

Ineffective material handling leads to wasted time and resources, impacting productivity and safety. But don’t take our word for it—see the success stories! Our case studies highlight how we’ve transformed aerospace logistics, from reducing worker comp claims to ensuring smooth and efficient operations.