Caster wheel brakes can slow and stop a cart as a backup to operator strength and to reduce strain. And they can help prevent carts or racks from moving unexpectedly, preventing product damage and employee injury.

For heavy-duty applications, there are several different caster wheel brake types with their own set of benefits. A quick review will help you determine which would be the best for your application.

These brakes utilize a foot pedal on the side of the caster, so the operator doesn’t have to constantly bend over to apply the brake.

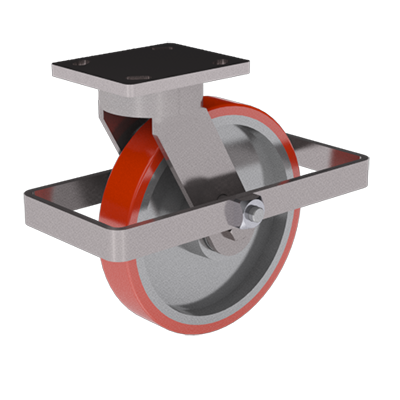

Single Side Caster Brakes

When all the casters attached to a cart or rack are equipped with single side wheel brakes, they do an exceptional job at keeping a load stationary. This brake can be applied to a variety of caster styles, as well.

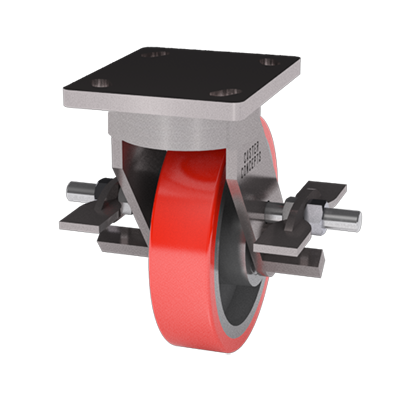

Dual Side Wheel Brakes

This wheel brake requires the user to tighten the brake shoe against the caster tread. While it does offer robust stopping power, it is not as ergonomic as the other options. This type of caster wheel brake is good for preventing motion for caster wheels with heavier tread, but it is not the best solution for certain types of shock-absorbing wheels or those made from softer, more flexible materials.

Caster Brakes provide excellent stopping power for heavy-duty loads.

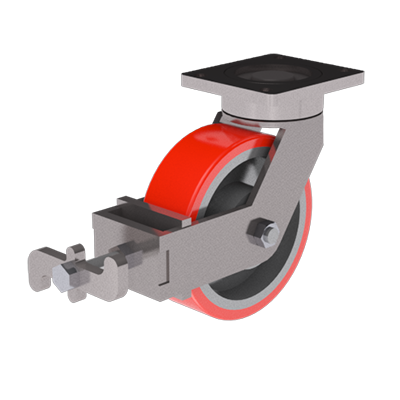

Poly Lock Brakes

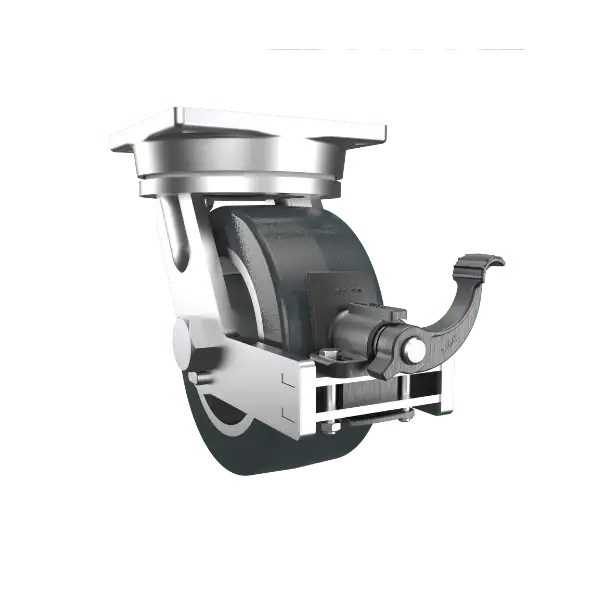

These foot-activated brakes are designed for heavy-duty loads. They can be installed in two ways – toe out and toe in – to best suit your unique application. The levers are easy to engage either way and provide excellent, reliable stopping power.

Pneumatic Poly Cam Brakes

Poly cam brakes are much like traditional poly lock brakes, but the brake shoe offers more (and more fluid) movement to compensate for thicker pneumatic tires. An advantage is like the standard poly lock brake, this one is also foot-operated and is relatively easy to engage and release. This works very well for heavy loads that require plenty of shock absorption but still rely on good brakes to keep loads stationary.

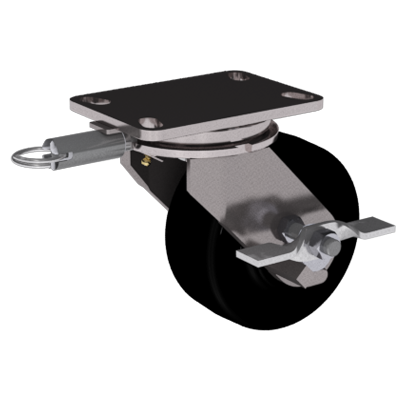

If you rely on pivoting heavy-duty casters to move loads, then you might understand the difficulty involved in properly lining up your casters for access to the foot-activated brake. Wrap-around brakes solve this problem. They give operators brake access from all angles, no matter how the caster is oriented. This can save time and keep employees safer, all while reducing frustration.

Investing in locking casters with brakes enhances safety and control and contributes to increased ROI by reducing ergonomic injuries. Explore our collection of locking casters today and experience the reliability and performance they offer in your material handling operations. If you are still unsure of the best option, contact the experts at Caster Concepts today. With some information about your needs and your application, you can easily discover the best casters and brakes for your individual projects and facility.

What is the difference in a Caster Brake and a Caster Lock? Check out this video:

The cam brake is used on lighter-duty casters. This brake provides an efficient, cost-effective hub braking system.

The dual side brake is a cost-effective hub brake. Each brake lever must be engaged by the operator.

The face contact brake is activated by tightening the brake shoe against the wheel.

Similar to the standard poly cam brake in operation, the pneumatic poly cam brake offers a greater movement of the brake shoe to compensate for pneumatic tires. The brake is foot-operated.

A polyurethane lock roller engages a steel brake shoe against the tread of the wheel providing positive engagement of the tread. Levers can be mounted “toe out” (shown) or reversed to “toe in.”

The single-side brake is an economical brake for medium heavy-duty casters with 6- to 12-inch diameter wheels.

The wrap around brake provides total access to the braking system regardless of the caster orientation.

Superior holding power starts here with Caster Concepts’ new PowerStep, a heavy-duty brake that holds and prevents a cart from rolling utilizing positive engagement and disengagement.