Caster Concepts recently worked with a company that builds cost-effective primary and backup power solutions — such as the control centers for AI centers’ server farms. These control centers play a crucial role in optimizing AI infrastructure’s performance, reliability, and security. The control center serves as a command and control hub, providing the tools and features that ultimately contribute to the success of AI-driven applications and services. These buildings can be 53 ft. long and 18 ft. wide, weighing 250,000 lbs.

Caster Concepts recently worked with a company that builds cost-effective primary and backup power solutions — such as the control centers for AI centers’ server farms. These control centers play a crucial role in optimizing AI infrastructure’s performance, reliability, and security. The control center serves as a command and control hub, providing the tools and features that ultimately contribute to the success of AI-driven applications and services. These buildings can be 53 ft. long and 18 ft. wide, weighing 250,000 lbs.

However, moving these large structures through assembly was proving not to be cost-effective, as frequent caster failure resulted in continual caster replacement and downtime.

|

Before Caster Concepts, the conventional machine mover skates used in the production process and out in the yard were proving inadequate, resulting in frequent skate wheel breakdowns. This incurred hefty replacement costs, estimated at $400,000 annually, and led to significant production downtime.

Another challenge the company faced was finding a caster manufacturer that would work with them on this problem and develop a critical transport solution. The control center manufacturer had contacted other caster manufacturers who did not want to take on a complex challenge that couldn’t be solved using standard off-the-shelf casters.

RELATED: MS spring-loaded casters 101: Everything you need to know.

Paul Van Dellen, the Outside Sales Consultant, collaborated closely with the control center manufacturer and our engineering team in a series of consultations.

The length and weight of these structures proved challenging. The first trials saw bearing failure during the initial move.

The length and weight of these structures proved challenging. The first trials saw bearing failure during the initial move.

The next problem was making the building pivot on its center point on uneven ground. Adding a heavy-duty spring-loaded rigid center caster to the skate solved this problem. This engineered solution was necessary for moving and loading the structures when transporting.

Further analysis and consulting resulted in developing and implementing a custom-designed skate.

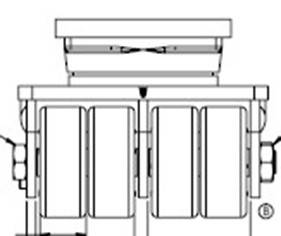

This skate featured two quad-wheel 91 series rigid casters, each equipped with four 6″ x 3″ wheels, with each wheel featuring a load rating of 40,000 lbs.

By following through with extensive testing and refinement to provide an optimal material handling solution, a strong relationship with the customer was built. If you have a critical material handling application that needs a unique solution, contact the solutions experts at Caster Concepts.