Caster bearings are an important part of the caster wheel.

In the comparison of roller bearings vs ball bearings, Roller bearings are generally used for manual applications and walking speeds. High-speed applications require precision ball bearings, which are typically maintenance-free. Tapered bearings are used for abusive applications such as side-impact loading and heavy loads.

Whatever the application, Caster Concepts offers a variety of heavy duty industrial bearing to suit your needs.

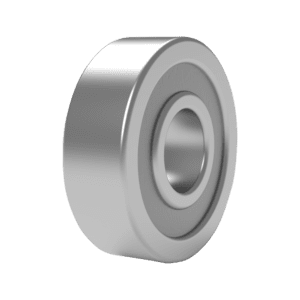

Bearings are machined with hardened raceways. Ideal for applications where maximum rolling ease and quiet operation are needed. Best suited for light to medium-duty loads. Bearing is pre-assembled and the entire unit is mounted in the wheel.

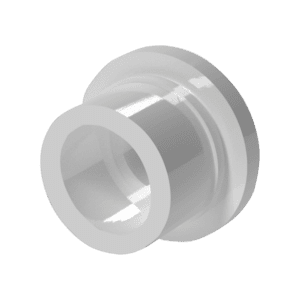

Delrin bearings are extremely durable under a wide range of temperatures, humid conditions and are corrosion resistant. Wheels with the Delrin bearings are well suited for applications such as steam cleaning or where excessive water or liquid is present.

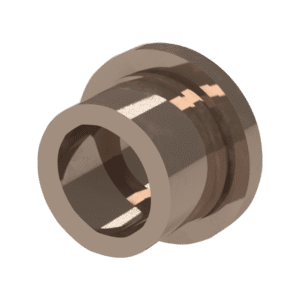

Oilite bearings are impregnated with oil that self lubricates during use. It is resistant to corrosion and suited for wet applications, slow speeds, high heat and very low maintenance.

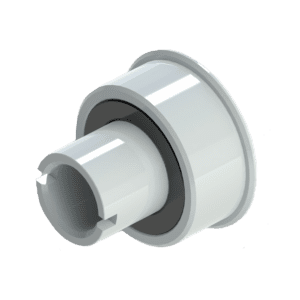

Recommended for maximum rolling ease with no maintenance lubrication required. Quiet operation for medium-duty to heavy-duty loads. Not suggested for severe side or impact loads.

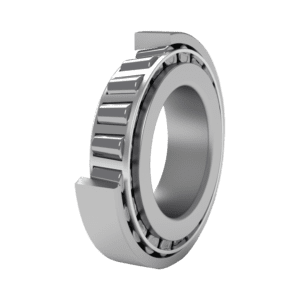

The precision tapered bearing is the most effective bearing for heavy loads. It is capable of absorbing excessive side thrust loading and can be used where high speed operation is essential. Bearings should be periodically inspected to ensure proper adjustment.

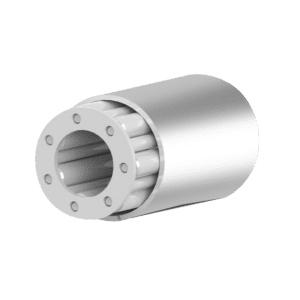

The roller bearing is capable of carrying a greater load than the same size diameter ball bearing. It has a split outer race shell into which the roller assembly is inserted. The bearings are contained by hardened washers.