If you type “Heavy Duty Casters” into Google, you get all sorts of odd results. You get results on furniture casters, chair casters, Heavy Duty casters from Lowes or Home Depot. You can even find casters from Uline and Grainger. While their offerings may be “Heavy Duty” in their worlds, the team at Caster Concepts would like to set the record straight on what a Heavy Duty Caster really is.

Definition of a Heavy Duty Caster:

80 Series Caster

For us, this is the 80 series casters and above. Wheel diameters for these casters range from 6″x3″ on up. They can be dual wheel casters or single casters featuring reinforced legs.

Heavy duty casters are designed to take abuse and keep on rolling. The wheel cores are either solid steel or grey iron. High-grade urethanes are used as tires and are designed to withstand high loads and high speeds. The swivel sections are forged and heat treated – no stamped options here. High-strength ball bearings and high-grade, extra tacky greases are used. These are what we refer to as Heavy Duty Casters, and I think our rivals – Hamilton, Albion, and RWM would agree with us.

The reason we use forged and heat-treated swivel sections (and in most cases – bearings) is because our casters are meant to be used in abusive applications. Nobody ever thinks of a caster or wonders what type it is (unless you work at CCI!) until it stops working. That is why swivel sections have to be overdesigned to carry heavy loads, take impact forces, and keep on working. Forged steel has better grain structure and is stronger than a cast part. Heat treating the part then improves toughness, wear resistance, and impact strength.

Our wheel cores are solid grey iron or steel for the same reasons. The wheels are always under compression and need materials that have high compressive strengths as well as resistance to impact. Whether it’s running over expansion joints to rails to even curbs. Our wheels have to be designed to take a beating and keep functioning. This is why we also use higher strength, high-quality urethanes. Nobody wants their urethane tire chunking out because they hit a pothole.

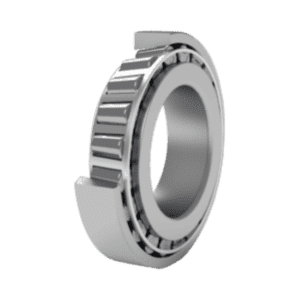

The precision tapered bearing is the most effective bearing for heavy loads

We don’t skimp on the grade of ball bearings or grease used either. These need to be high strength for all of the reasons above and the grease needs to be extra tacky – with the limited range of motion most casters go through, we can’t have the grease getting pushed out of the way of the ball bearings when in use.

If you are looking for a “Heavy Duty Caster” that can withstand harsh environments and carry anywhere from 5,000 to 100,000 pounds – you’ve come to the right place.

If you are looking to upgrade your furniture or chair casters, or put better casters on your toolbox – we would suggest you visit Lowes, Home Depot, or Grainger.