Many customers have asked, “How do I know what industrial caster or wheel to use?” Many specifications need to be figured out when determining what you need in your caster.

The three most common questions that help us determine which caster include:

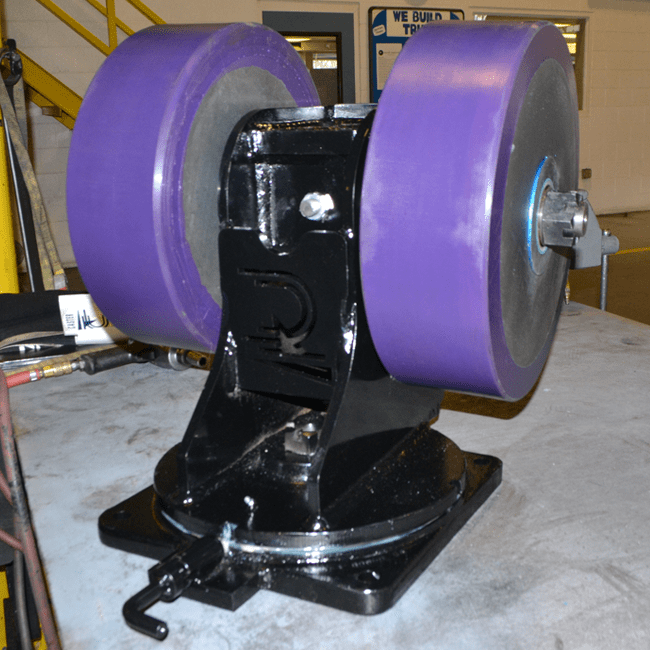

The surface an application will be rolling on also plays a significant factor in determining wheel material. If the floor is smooth like indoor concrete, and there is minimal to no floor debris, then a polyurethane wheel will most likely be a good choice. Poly provides a softer material for rolling on surfaces than a steel wheel, which can damage your floor over time.

The surface an application will be rolling on also plays a significant factor in determining wheel material. If the floor is smooth like indoor concrete, and there is minimal to no floor debris, then a polyurethane wheel will most likely be a good choice. Poly provides a softer material for rolling on surfaces than a steel wheel, which can damage your floor over time.

Of course, this also depends on your application. For instance, if your application runs on a rail, a steel V-groove wheel may be necessary to stay on the track and provide a higher load capacity than polyurethane. Suppose the primary use for your application is going to be outside, in the elements, and over rough and uneven terrain. In that case, an industrial caster with a pneumatic wheel will be the best option for more rugged use.

There are also spring-loaded casters to help protect the more delicate large materials from bouncing, breaking, and causing too much noise during movement. Another caster option that we have is called a Swivel on Swivel. This takes two swivel components and stacks them on top of each other. This can be a good fit when an application is being moved within a tight space because it reduces the side-to-side sway of the application during initial movement.

In heavy duty industrial applications, one might think that the ease of movement doesn’t matter because there isn’t a person straining or risking injury. However, ease of movement still matters because it means less strain on automated vehicles. This translates into longer battery life and a power savings advantage. This may come into play in facilities using AGVs to move a job throughout an assembly line from one processor to another.

On our Caster Concepts website, we also provide our customers with a Learning Center that explains the many aspects of the casters we make so that they can have a better understanding and do research when it is convenient. This can help with the decision process before ever speaking with a salesperson.