Push Force Reduction Over 55% Earns TWERGO® an Industry-First Ergonauts Approval

The approval verifies that TWERGO® reduces push forces by over 55% so cart operators reduce the risk of ergonomic injuries, which are the leading causes of lost time and medical costs.

How to Choose the Right Heavy Duty Caster

Optimizing your material handling effectiveness is a balance of lowering push/pull forces and caster noise, while extending wheel life and load capacity. Choosing the optimal design starts by answering these 10 most-asked questions.

Why Caster Concepts is a Leader In Material Handling

Designed and manufactured in the USA, our material handling solutions are used by many of the top 100 manufacturers across major industries. Our product specialists can visit your facility, analyze your needs and deliver a solution that offers better ROI tailored to your specific application.

Improving Heavy Duty Material Handling Effectiveness

Solutions for All Industries

Automotive

Automotive manufacturing is an extremely competitive industry, one that is constantly looking to increase productivity and gain greater efficiency while maintaining high standards for quality and safety.

This is an industry where casters play an important role, and one that Caster Concepts excels in.

When carts are required to carry heavier loads without increasing the force to move them, our casters reduce friction and eliminate scrubbing for improved efficiency and safety.

Aerospace

Caster Concepts builds strong relationships with our Aerospace customers by focusing on their design and manufacturing needs.

Collaborating closely with our customers’ designers and engineers enables us to turn around models and drawings quickly. And in an industry where there is little margin for error, these important interactions help us to develop specific-use casters with built-in safety factors to prevent caster failure.

We also have a variety of products designed with ergonomics in mind to help our customers move heavy loads easily and without incident.

Marine

Manufacturers of marine and leisure vehicles have relied on Caster Concepts for help in improving safety, increasing productivity, and solving unique challenges that arise during the production process. This includes protecting boat molds and decks from cracking, providing ergonomic solutions to make moving and maneuvering heavy loads easier, and minimizing fiberglass buildup and other factors that decrease caster life.

- Load protection solutions to minimize cracked hulls and decks

- Ergonomic solutions to make moving and maneuvering heavy loads easier

- Durability solutions to extend caster life and reduce wear

Tire Manufacturing

In the tire manufacturing industry, as many as two hundred raw materials go into making a tire. These materials are transported to prep zones, storage areas, and the tire building machines themselves. This task involves using several material handling carts that deal with heavy loads and any number of scrap debris on the floor.

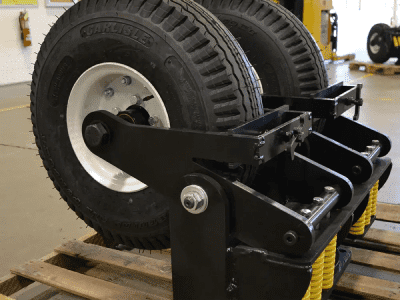

Caster Concepts has worked with many tire manufacturing plants to help them solve issues related to higher load capacities, overexertion, floor debris, and high-temperature environments. A great example is our 77 Series Dual Roll Ball Bearing with Twergo Wheels, which helped one company reduce push force in half. The in-house manufacturing of our poly tread formulations also helped to minimize wheel debris pickup, reducing rollability issues and providing longer life to caster wheels.

Agriculture and Heavy Equipment

The type of equipment required to build and maintain the heavy equipment of today needs to be as rugged and reliable as the cranes, tractors, bulldozers, and other heavy equipment themselves. Everything is bigger in the world of heavy equipment manufacturing, and that means substantial weight capacities that need to be moved safely, yet efficiently.

Workflow optimization is a greater challenge when parts weigh hundreds, even thousands of pounds. Carts and carriers are taxed with supporting massive loads, creating challenges and safety concerns. To help keep this industry moving, Caster Concepts designs casters and wheels specifically for these types of applications.

AGV Casters

Productivity gains are always on the top of everyone’s minds. That’s why Caster Concepts has caster wheels designed to save battery life and reduce motor torque on AGVs. These wheels also allow for more precise movements with little vehicle sway, allowing AGVs to move heavier loads without needing larger drive systems.

Caster Concepts can help you determine the best ergonomic caster and caster wheel for your application. With proper ergonomic casters, you can realize a better ROI through fewer injury claims and less downtime by reducing the initial, continuous, and turning push/pull force of your material handling carts.

Ground Support Equipment

Whether it’s casters on a luggage cart, low profile cargo handling cart, cargo dollie, or aircraft maintenance stand, these casters must withstand harsh elements, uneven surfaces, and the constant wear and tear they undergo daily.

Caster Concepts offers a complete line of ground industry casters that are up to par for the grueling demands of outdoor applications, including a complete line of aluminum casters that are lightweight and corrosion-resistant, yet durable.

Our ability to protect precious cargo with dependable and durable casters is something we have helped customers successfully accomplish for years. From aviation to the military, Caster Concepts provides industry-leading motion solutions from the ground up.

Conveyor Rollers and Wheels

Common conveyor belt problems can cause issues ranging from lost production to damaged products and injured employees.

Caster Concepts helps customers overcome these application challenges with conveyor wheels designed to lower rolling resistance, handle heavy loads and provide reliable and safe operation over time.

- Minimizing Tracking and Load Problems

- Reducing Wear and Seized Rollers

- Keeping Systems Rolling