Cracked fiberglass is becoming a prevalent problem in the boating industry. And no wonder. When you take an industry that is used to building a set amount of boats in a year then double or triple that in one or two-year time frame, problems can occur. As I continue to meet with more and more boat Manufacturers, this topic consistently gets brought up.

The name of the game is Build Big and Build Now. Since the start of Covid in 2020, the boating industry skyrocketed: It was one way for people to stay outdoors and stay sane in the midst of all the shutdowns and social distancing.

For the last two-plus years, this means running molds through the process as fast as possible while still producing a high-quality end product.

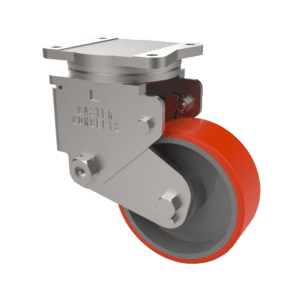

83 Series Spring Loaded Casters

With the correct casters, you can prevent most –if not all — of your fiberglass from cracking and minimize deck cracking(where we see this most of the time). Choosing the right caster will also help overcome the ergonomic challenges of trying to move more with less. Working on a solution to meet each customer’s specific challenges is a job that we take very seriously.

One, the decks are not supported properly on the dolly, where high flex areas or uneven load distribution can be prone to cracking. And two, the casters that are being used are too rigid and do not offer any flexibility.

When casters are too rigid, the best solution is to go with a spring-loaded caster. These types of casters come in a wide variety of weight capacities, wheel sizes, and configurations.

When choosing a spring-loaded caster, there are a few keys to determining what casters are right for your application. These include:

Once you have thought about all of these things the best way to move forward is to reach out to your trusted caster and wheels supplier and talk about your application. They should be able to work with you to design a caster that is perfect for your application.