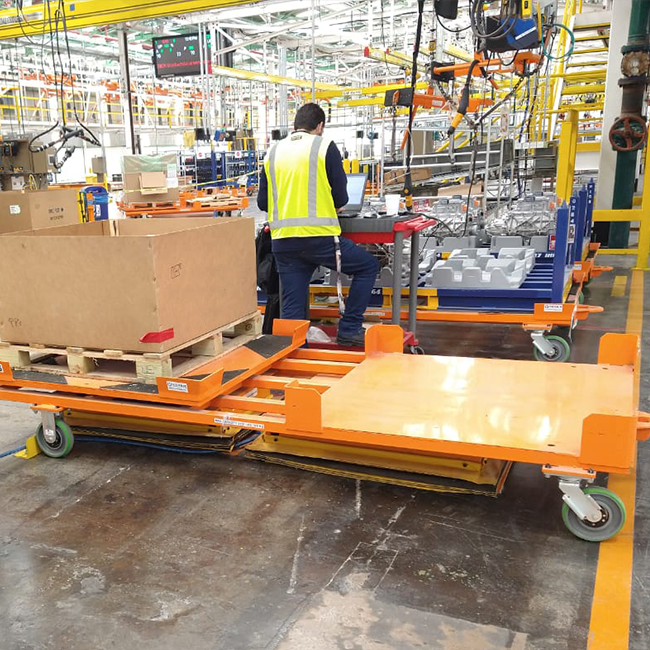

Driving Savings, Safety, and Efficiency in Automotive Assembly.

Innovative Solutions to Eliminate These Common Problems.

Balloon tread wheels failing under pressure from high speeds.

Low quality casters that fail and cause costly damage your floors.

Time wasted waiting on tuggers and other workers to move a cart.

Make moving heavy carts a safe, one person operation.

Problem: Wheels fail under higher towing speeds and abuse, causing frequent replacements.

Hysteresis (heat) builds up at higher speeds, causing a caster wheel’s polyurethane to tear off the metal core.

Solution:

- ERGOXCEL™ casters with sealed, maintenance-free swivel bearings.

- Exceptional maneuverability and durability.

- Extended savings with less caster replacement.

- Reduced maintenance and costs.

- Read more about common types of wheel failure.

Problem: Low-quality caster wheel failure, causing frequent replacement and extensive damage to floors.

Low-quality wheels are prone to break under heavy loads and need constant replacement. These caster failures also cause expensive damage to floors.

Solution:

- 5,000 lb. capacity Heavy Duty Caster designed for difficult and abusive industrial applications.

- Reinforced legs provide additional strength when side loading.

- Tear-resistant poly wheels for higher strength and extended wear.

- Real-World Application: 77 Series Casters Reduce Caster Failure and Downtime On Indoor-Outdoor Paint Skid.

Extra Heavy Duty Kingpin Caster – 5,000 lbs. Capacity

- A tough caster designed for difficult and abusive industrial applications

- Reinforced legs provide additional strength when side loading.

- Tear-resistant poly wheels for higher strength and extended wear

Kingpinless Maintenance Free Caster – 3,500 lb. Max Capacity

- Dual sealed precision bearing for smooth rotation and movement

- Supports 3″ wide wheels up to a 10″ diameter

- Reduces push force while wheels are not parallel

TWERGO® XTREME

- Great for AGV’s, Tuggers, and material handling carts where high weight capacities are needed.

- All wheels rotate independently of each other and are designed to minimize rolling resistance.

- Available in two-and three-wheel configurations with a maximum load capacity of 3,500 per wheel.