Find Your Caster

Tag: Flat Faced Casters

Easy swivel casters, unlike rigid casters, which travel in a straight line, have an additional swivel joint above the fork, allowing the fork to rotate 360°. This makes it easy to move the wheel in any direction without changing its orientation. How well these casters perform depends on a few things. The first is swivel lead. This is the distance from the vertical centerline of the caster swivel section to the vertical centerline of the wheel. By extending or lengthening the lead, a loaded cart is easier to turn as it requires less force to get moving. However, increasing the lead on an industrial caster also leads to a larger turning radius.

Ergonomic casters create less friction with the ground. This benefit can significantly reduce the force exerted to move and turn a cart or dollie. Easier movement results in reduced risk of injury and the associated costs and potentially increased productivity. These benefits are realized with tapered treads, independently rotating wheels and round wheels. In addition, Swivel on swivel designs offer longer leads than conventional casters and reduce the force required to rotate the caster and start it rolling while reducing side-to-side shifting. Higher-profile wheels can also increase carrying capacity without changing wheel size.

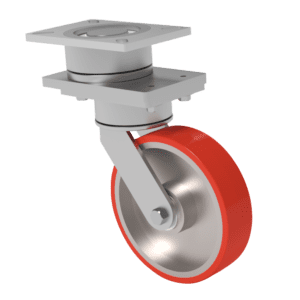

A flat-faced caster is a caster wheel with a flat face as opposed to a tapered or round face. A flat face is better for heavier load capacity because the weight is dispersed over a larger footprint, which covers a larger area on the floor.

The maintenance-free caster mitigates maintenance and repair time due to its pre-greased and sealed ball bearing. For many facilities, this eliminates the blocks of time required to perform preventative maintenance and repair on carts and dollies. Another situation where a maintenance-free caster excels is keeping out debris such as dirt or metal fragments. Painting and sandblasting facilities, boat manufacturing, metal fabrication, and even outdoor applications use maintenance-free casters due to their ability to repel/prevent foreign substances from entering.

Flat Faced Casters

A flat-faced caster is a caster wheel with a flat face as opposed to a tapered or round face. A flat face is better for heavier load capacity because the weight is dispersed over a larger footprint, which covers a larger area on the floor.

Showing 1–12 of 93 results

-

Compare

Compare10×2 ErgoTread Swivel On Swivel (SoS) Caster

SKU: 134-10202-40-1Top Plate Size: 5 x 7.25 Capacity: 2,185 lbs Overall Height: 15.25 in Caster Material: Steel