A prominent boat manufacturer had a severe problem with their boat molds breaking. The issue was excessive shock loading when these 80,000 lb.(and very expensive) molds were being loaded for transport.

They tried different types of casters but could not find one that could handle the loads and protect the molds. Finding a suitable solution became paramount, as the strain on productivity was drastic, with excessive downtime, lost product, and missed deliveries straining the business.

The logical step was turning to the industrial material handling experts to assess their specific material handling needs.

Caster Concepts thoroughly analyzed the loading and transportation processes, including examining the carts’ design and material handling procedures. This led to opportunities for optimization and risk mitigation by identifying casters that would distribute the load better and absorb shock.

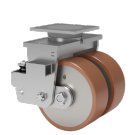

The solution was Caster Concepts’ specially engineered Extra Heavy Duty 104 Series Casters.

The 104 Series Casters are designed to protect heavy loads. They feature a unique spring-loaded design that absorbs shock, reducing the impact on carts and payloads. These casters are built to handle weights of up to 80,000 pounds, making them ideal for the boat manufacturer’s needs.

The shock-absorbing casters effectively handled the total and shock loads, reducing the risk of breakage. This enabled the manufacturer to reduce the scrape rate by $5M monthly for an average annual savings of $60M!