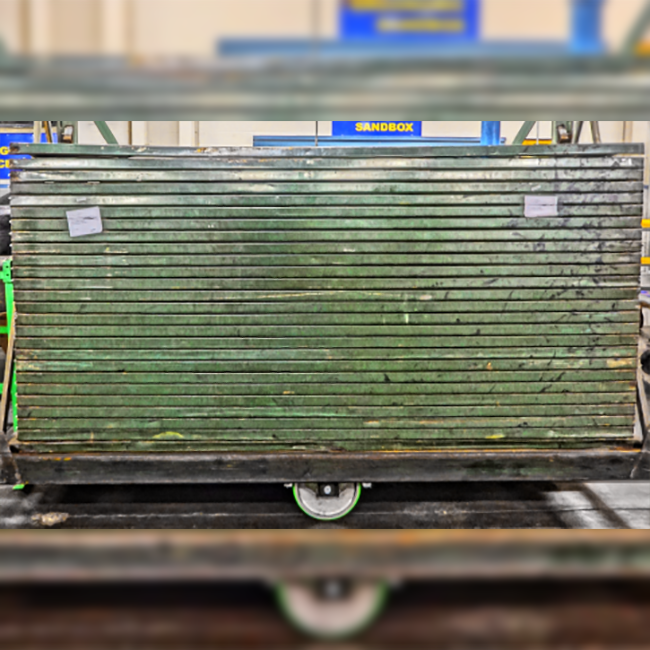

Tire weights are increasing with the development of electric vehicles. For tread carts, this weight adds up quickly. At one facility, typical carts weights easily push 4,500 lbs. when fully loaded. Initial push forces numbers associated with these loads can run between 85 and 100 lbs. That’s a lot of rubber to get moving.

55 Series Caster With Twergo Wheel

Because of the cart’s weight, the caster placement was as important as which casters were chosen. Caster Concept’s engineering optimized a diamond pattern configuration with an emphasis on weight distribution. This setup consisted of four 3-inch-wide rigid casters stacked in the middle of the cart to reduce push force. This lineup also created a narrower footprint. The 8-inch tall rigid casters featured a split wheel design to handle most of the weight, and help to reduce scrubbing when pivoting the tread trap. Additional swivel casters on the front and back of the cart aided in maneuverability. The diamond pattern setup also minimizes the swivel casters from rotating.

With Twergo Extreme casters equipped on the carts, push force was reduced by 35-40%, and push requirements met and exceeded all specifications for that plant.