Heavy duty. It’s a term that refers to something designed or built to withstand substantial stress, strain, or use. Equipment or machinery designed to handle intense or demanding tasks is often beyond standard capabilities.

99 Series Swivel Casters

At Caster Concepts, we define heavy duty casters as five thousand pounds and above capacity per caster. These range from heavy-duty to super heavy-duty (17,000 lbs. and up). The total weight you are moving determines what capacity caster you should use and if a heavy-duty caster is even required.

When a customer reaches out on a heavy-duty application, we must get the speed, load, and duty cycle right. Most of the time, we divide the total load by three (as no surface is going to be perfectly even, there will be times when only three casters will be in contact with the surface). This helps us determine an additional built-in safety factor. For example, if the total load is 12,000 lbs., you want each caster to handle 4,000 lbs.

If you were to google heavy-duty casters, you would get anything from an inexpensive stem caster (like the kind you would find on an office chair) to a dual-wheel caster rated for ten miles per hour. Everyone has their definition of heavy duty. Caster Concepts’ expert team of engineers likes to work on the big stuff.

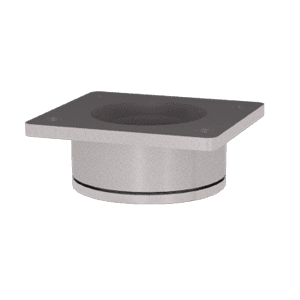

Swivel Section

Heavy-duty casters have a more extensive swivel section to increase load-bearing capacity. While heat-treated raceways eliminate brinelling of the surface when the casters are subject to potential shock loading, adding standard polyurethane swivel casters enhances their overall performance. The swivel sections of heavy-duty casters can use one of three types of swivel bearings for robust and rugged applications.

The first of the three options is a swivel section machined for single ball bearings. The unique design of this raceway places ¾” diameter load/thrust ball bearings in shear, locking the swivel section together. This design provides a high-strength swivel section that will swivel easily under hefty loads. This is the most common type of heavy-duty swivel caster that Caster Concepts offers.

The second of three options is a swivel section with a sealed precision ball bearing with hardened raceways and neoprene seals. This makes the swivel section of the caster completely maintenance-free. Its smooth rotation combined with an extended lead helps lower ergonomic forces. More and more customers are moving to this swivel section to eliminate maintenance requirements.

The third and final option of swivel bearings is a swivel section with a considerable precision machined raceway incorporating a precision taper bearing and taper thrust bearing. The tapered load bearing and thrust bearing are used where high load capacities are required and where there is constant use under load.

Unique applications make them one-off builds, and that is where Caster Concepts excels. We can make it a little taller or wider to hold the load and do the job. Depending on your needs, customization can be a complete custom design or simply changing the mounting pattern, caster height, swivel lead, bearings, or other straightforward changes. Whatever your needs, you’re assured of a heavy-duty caster with increased strength, durability, and capability compared to our standard light or medium-duty casters, making these casters suitable for demanding or challenging situations.