Industrial casters, or wheels used in industrial applications, can solve various problems and challenges, from preventing injuries to increasing worker productivity. From steel casters to polyurethane casters, here are five examples of the practical applications industrial casters provide.

One of the first and foremost benefits is mobility. Industrial casters provide easy mobility for heavy equipment, machinery, and other objects within a factory or warehouse, making moving items from one location to another easier.

This ease of movement has much to do with a caster wheel’s rolling resistance. This, in turn, is affected by the material used in the wheel’s construction. Polyurethane wheels offer some of the best ergonomics regarding low rolling resistance. Choose a pneumatic wheel for noise and shock absorption, and go with forged steel if you are moving extreme weights.

For safety concerns, equipping casters with brakes, locks, and shock absorbers can improve safety in industrial settings, reducing the risk of accidents and injuries.

For heavy duty applications, our caster wheel brakes include single and dual side brakes, face contact brakes, wraparound, and poly lock and poly cam brakes. All these types of brakes provide increased safety and stopping power.

Another popular option is our toe guards, a simple and very effective option to help protect an operator’s foot and prevent serious injuries.

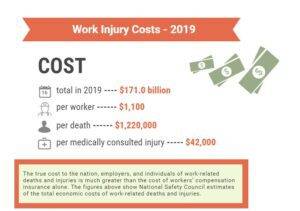

Ergonomics is another significant benefit and can even be tied to safety regarding preventing injuries. Designing casters featuring smooth and effortless movement improves ergonomics for workers and reduces the risk of strains and other damages.

Worker Injury Costs: https://injuryfacts.nsc.org/work/costs/work-injury-costs/

A significant cause of overexertion injuries is workers who must move loads weighing thousands of pounds. This weight requires powerful push force to start, turn, and keep a material-handling cart moving throughout the day.

Ergonomic casters are designed to create less friction with the ground. Less friction makes moving and turning a cart or dolly easier to reduce the chance of operator injury and the associated costs.

To help our customers pass internal safety standards. Other options to reduce push force include using a giant diameter wheel, a split wheel design, and swivel casters.

RELATED: What safety options do I have once my dolly is built?

Moving heavier objects quickly also increases efficiency and productivity as workers complete tasks more rapidly and with less effort. This efficiency also benefits battery life, as the more effortless movement of a battery-powered AGV requires less power.

Customization: Industrial casters can be customized to meet the specific needs of a particular application, including load capacity, size, and other features.

Some examples of the need to customize a caster happen when the original spec’d caster is no longer available, or the customer needs a more durable option that still fits the original design parameters. Other areas where Caster Concepts developed a caster for a customer’s unique application include:

Using industrial casters has many benefits. They can even be more cost-effective than other solutions, such as cranes or forklifts, in specific applications and provide a long-lasting solution that can withstand wear and tear.