Any caster not listed as a standard caster is a custom caster.

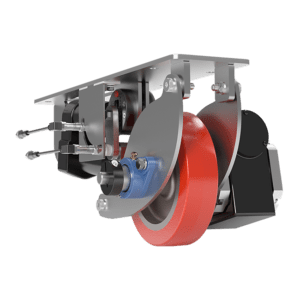

Any caster not listed as a standard caster is a custom caster.A custom caster or a specialty caster has a broad definition and is essentially any caster not listed as a standard product in the catalog. This could be as simple as changing the mounting pattern, overall height of the caster, the swivel lead, bearings, or other simple changes. A custom caster can also be designed from scratch to handle a variety of applications. This includes heavy loads, high speeds, shock absorption with specific parameters, a replacement conveyor roller, or anything else that helps you solve a material handling problem.

Our customers tend to go the custom route when they are trying to retrofit casters into a legacy operation. Usually when the originals are no longer available or there’s a need to maintain special mating heights of equipment. Custom casters are also popular in the aerospace industry when moving very heavy, complex loads that require special floor loading stress, shock absorption, and safety factors. Other times, a customer has an application where catalog casters are not holding up, and they are looking for a more durable option that still needs to fit into the same design parameters.

Let’s look at the two top concerns people have with custom casters: cost and lead time. Caster Concepts has a manufacturing system set up to produce casters to order. So simple changes like mounting pattern, height, etc., don’t add to lead time or impact cost much. We are a made-to-order business, so we do not have finished products sitting on a shelf waiting for someone to order them.

This means we laser cut, form, weld, and assemble casters as ordered. So we can handle simple custom changes with minimal impact to cost or lead time. The more customized a caster is regarding the swivel section, wheel bearings, or the spring rate on shock-absorbing casters, the more drastically it affects the cost and lead times. Bearing availability and other special components can also be a detriment to lead times. Costs can also change drastically depending on how many specialty items are needed. Casters can go from $200 to $1000 by changing the bearings to special high-temperature versions.

This is where our caster configurator comes into the picture. If you believe you are a fit and need a custom caster, our caster configurator tool allows you to develop your custom solution directly in your browser. You can then download a 3D model in a variety of formats. The same would apply to configuring a variety of wheel types.

So, if you have an odd application, extreme application, or are having issues finding replacement casters, custom casters may be the right path for you. And depending on the needs, manufacturing custom casters with similar costs and lead times compared to standard “off the shelf” products is also possible. Custom casters also give you peace of mind by having the technical design and the engineering calculations to back them up.