How often have you bought something on price alone, choosing the product or service strictly because it had the lowest price? In the caster world, when price becomes the driving factor, there are times when the result is an undersized, imported caster rig. While we understand the sensitivity to pricing, it is important to know what goes into a caster’s actual price.

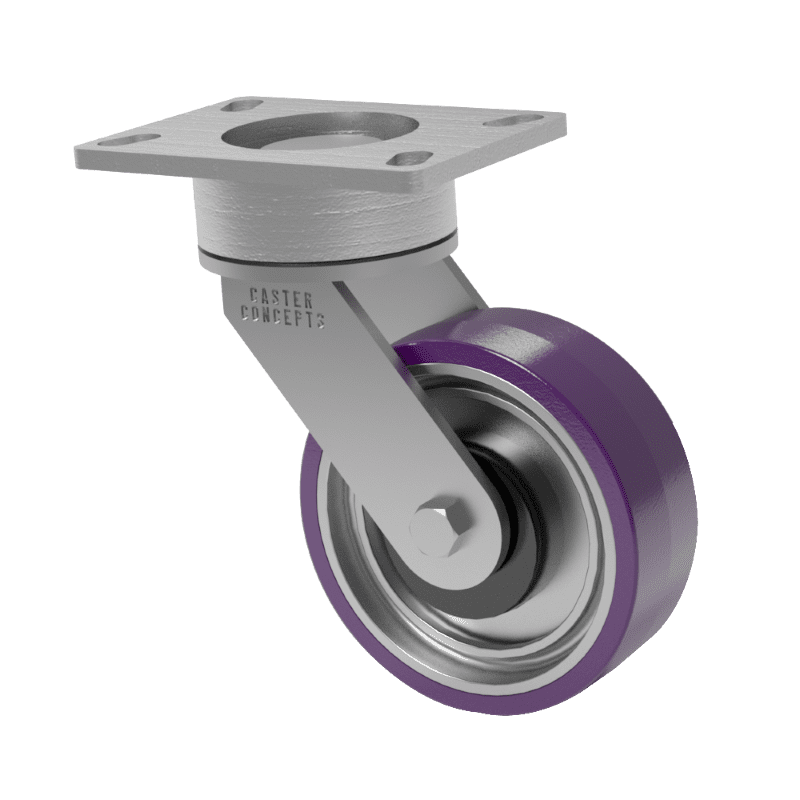

Using standard swivel sections and standard wheel castings is one area that can significantly help in keeping overall costs down. Anytime you can use “off the shelf” parts, you’ll always save time and money. For a more in-depth look at this, go to our blog: What Affects The Cost Of A Caster?

Two casters may look the same or seem very similar. However, the bearings packed inside their swivel section can be very different. Two very common bearings are precision sealed and ball bearings. Precision sealed bearings do not require greasing (they are maintenance free) and have a longer use life rating than standard ball bearings. Precision bearings also have a higher purchase price but usually have a lower overall cost when adding in replacement and maintenance costs.

Now that we have gone over a few items that affect the price of your caster, here is a quick overview of the price range of our casters. These prices cover our caster series based on caster type and weight capacity.

Setting up a CNC machine for made-to-order jobs also affects the overall cost, as the setup time is the same per job regardless of quantity. The setup time for one piece will be the same as the setup time to manufacture five pieces or even 100 pieces. Many of the machined components are standard components of an industrial caster. But there will always be specially configured casters that require retooling to make parts that we need for a specific application.

Another important factor to consider is weight capacity as it relates to safety. Once you know your overall load weight, add approximately 30% more for circumstances where not all of your casters are touching the floor simultaneously. Adding in this extra layer of security can help prevent caster failure. And environmental factors, such as moisture and temperature, will also affect your caster choices, such as using an aluminum caster and sealed bearings.

We hope this helps you in your caster and caster wheel choices. If you have any further questions, please don’t hesitate to contact us. You can access our live chat below or call us at 517-343-1491.