Dual wheel or double wheel casters can play important roles in facilities of all types, but what are the advantages of having two wheels in a caster instead of just one?

We’ll explore the benefits of dual wheel casters and why they might be the right choice for your applications, especially for certain applications when load capacity, space restrictions, and maneuverability are important.

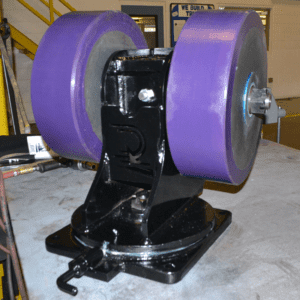

Let’s start with what exactly a dual-wheel caster is. These types of casters have two wheels for every top plate. This allows them to bear more weight and distribute it evenly, an important consideration for heavy-duty industrial applications. Now, let’s look at some situations where a dual-wheel caster might be the right choice for you.

The number one reason people choose double-wheel options over their single-wheel counterparts is the weight of the load. Sometimes, a single caster wheel isn’t strong enough to support an entire load.

Remember that weight limits apply to each wheel, so rather than having one large wheel that might support 3,000 lbs, you could have two small wheels that help 2,500 kg each, giving you a 5,000 lb. weight limit for that particular set of casters. This is important to consider, particularly when height and wheel size are factors.

In most cases, larger-diameter casters support more weight. With that said, to move heavy loads with single-wheel casters, the casters can grow so high that the load is higher than safe. Double-wheel casters allow for smaller diameter wheels, translating to a reduced cart height without sacrificing its load-bearing capacity. In most cases, the height can be reduced by as much as 30% while maintaining the same capacity, simply by switching to dual-wheel casters.

Many manufacturing facilities are busy, and there’s only so much space. Carts designed to carry tremendous loads often take up much floor space, which can cause problems in these facilities. Dual wheel casters allow you to spread weight proportionately over a bigger wheel surface. This weight distribution minimizes the damage to floors and reduces the cart’s overall size to save space on the plant floor. In the grand scheme of things, this can make a tremendous difference.

Another significant advantage of dual-wheel casters lies in their maneuverability. Single-wheel casters can be difficult to maneuver when under a great deal of downward pressure. The heavier the load, the harder it is for the wheel to move and swivel.

Distributing the load across more wheels (for example, eight wheels instead of just four) reduces the pressure on each wheel and makes it far easier to swivel. Dual wheels reduce friction and “floor scrubbing,” which makes loads easier to move and may reduce workplace injuries.

Dual wheel casters provide extra load-bearing capacity, safely keep loads lower to the ground, keep carts and racks smaller, and even increase a cart’s maneuverability, which helps improve workplace safety and morale. Still not sure if going dual is cool? Contact us for more information or call 888-986-0244. We can help.