If you’re embarking on the journey of selecting casters for your industrial applications, you’re likely to have a series of questions. Doug Backinger, the Vice President of Sales at Caster Concepts, answers the top four caster questions asked by new customers and specifying engineers to provide valuable insights into the world of choosing and customizing industrial casters. Let’s dive in:

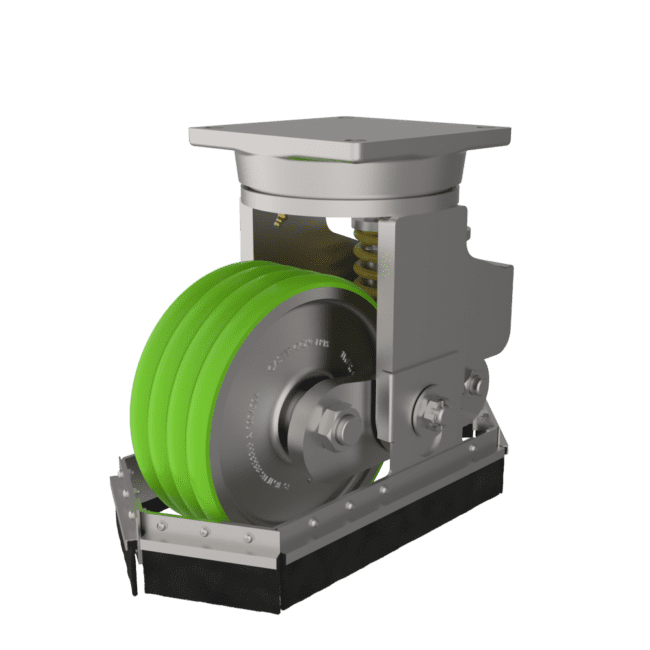

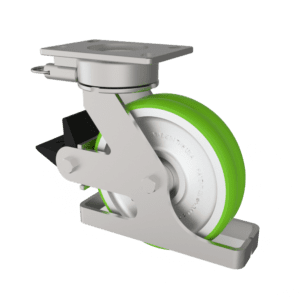

Caster brake and tow guard

The cost of stock and custom casters can vary widely, depending on several factors. These factors include your application, load capacity requirements, and specific needs like swivel locks, brakes, toe guards, or different types of urethanes. Custom caster options, such as custom polyurethane wheel cores or swivel sections, can also impact the cost. Caster Concepts offers a range of options to accommodate various budgets, and you can find cost ranges on our website.

Selecting the right caster begins with understanding your load capacity needs. Divide your load by three to estimate the load each caster should handle. While catalog ratings are given at walking speeds and intermittent use, high-speed or 24/7 applications require consultation with a Caster Concepts solutions engineer. Consider factors like durability, rollability, and environment to choose the caster configuration that suits your application best.

Yes, customization is possible. Whether you need minor modifications like a new top plate or longer legs or if you require a highly customized caster for a specific heavy duty application, Caster Concepts can help. Our ability to design and manufacture custom products allows us to meet unique requirements effectively with minimal effect on lead time.

.

Of all the common questions we get asked from new customers, this is a big one. Caster Concepts’ lead time for casters averages under a week, from final drawing sign off and PO placement. Lead times may vary based on complexity and quantity of custom casters, but ‘our investment in one piece flow and in house poly molding enables us to manufacture both stock and custom casters with the same lead time.

RELATED: LEAD TIMES FOR STANDARD AND CUSTOM CASTERS

By addressing the top caster questions new customers ask, Doug Backinger provides a solid foundation for anyone new to the world of industrial casters. If you have more inquiries or need further assistance choosing or customizing a caster, you can explore Caster Concepts’ Learning Center or contact our team for personalized guidance.

Thank you for starting your journey to spec out industrial casters with Caster Concepts. Their expertise and versatile solutions make finding the right caster for your needs a straightforward process.

We engineer material handling systems to maximize your productivity and reduce costs. For more information:

|