Selecting an industrial caster can be an overwhelming job, there are a variety of variables and challenges that need to be accounted for and solved which can be daunting. In this guide, we are taking some of the guess work out for you, follow each step so that you make the most informed Caster buying decision. If you are still unsure after reading through this guide, that is okay and quite common. But now you will be more prepared, and have a better understanding of what questions will be asked by one of our experts when working with them to determine the best caster for you.

For most, the biggest challenge is where to start! The first step is understanding the caster’s capacity. And to calculate the capacity, you need to determine how much of a safety factor is required. We suggest estimating the total load over three casters to ensure adequate support. When you’re dealing with uneven floor conditions, you can assume not all casters are contacting the floor. So, ensuring that the load can be supported by three out of the four casters allows for adequate safety.

The next step is understanding the application. We use a few questions to help determine the best caster for your situation. These include:

Once capacity and the application are understood, we can continue down the path of selecting a caster. One thing to consider is whether you need a shock-absorbing (spring load) caster or a non-shock absorbing (traditional) caster. A shock-absorbing caster is ideal for carrying fragile or expensive products, and you want to reduce vibration. Another reason to consider this type of caster is they help spread the load evenly and ensure all the casters are contacting the ground. You would typically go with your traditional non-shock absorbing caster outside of these situations.

Step 3. Caster Swivel Sections

Step 3. Caster Swivel SectionsNow comes the caster swivel section. The standard swivel sections are kingpin, kingpinless, and maintenance free. You would rarely select a kingpin caster unless you have a well-planned maintenance program or a unique application. The most common option would be a kingpinless caster which covers most of your applications. The third type, maintenance free, is best for ease of movement and eliminating routine maintenance. Once you select the style, you can choose the caster series based on the needed capacity. Make sure the capacity required is under the max capacity of that series. And here’s a tip: if ease of movement is an important consideration, add extra capacity/safety factor.

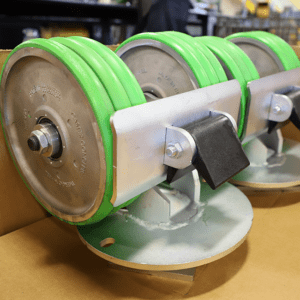

Selecting your wheel is next, and it is an area where understanding the application (Step 2) is most important. For high-temperature settings, steel or high temp plastic are best. If maintaining floor conditions is priority #1, you will want a softer material like polyurethane. If ease of movement is important, consider our Twergo or balloon tread and our TR 95A or PTMEG Ergo tread polyurethane. For heavier loads, you can use larger polyurethane wheels to protect floors. And to keep the overall height down, steel and Nytec wheels handle heavier loads in a smaller size.

When thinking about wheels, don’t forget another important consideration: your bearings. Traditional roller bearings are still important in higher temperature applications. Ball bearings are typically the better option for most applications, especially for ease of movement. Tapered bearings are best for rigorous applications that see a lot of abuse, such as shock and side loading.

Safety Add-on’s such as to consider. Brakes lock the wheels in place to prevent the caster from rolling. Swivel locks will lock the swivel section in place, typically at 90 degrees, to help maneuverability. Toe guards wrap around the caster to prevent injuries from rolling over the operator’s feet. brakes, swivel locks, and toe guards are also options

Thanks for reading this simple guide to selecting casters. Look for expanded information on each of the categories above, such as; understanding applications, swivel sections, wheel types, bearings, and add-ons.