Many of my customers want to know about preloading a bearing. Preloading your bearings is important, especially if you are using a wheel with a tapered bearing. The majority of applications will either use a tapered bearing, roller bearing, or ball bearing.

Roller bearings are all one assembly and get pressed in the center of the wheel. Roller bearings have a split outer race shell with a roller assembly inserted into it. These bearings are not sealed, so regular maintenance is required.

Roller bearings are all one assembly and get pressed in the center of the wheel. Roller bearings have a split outer race shell with a roller assembly inserted into it. These bearings are not sealed, so regular maintenance is required.

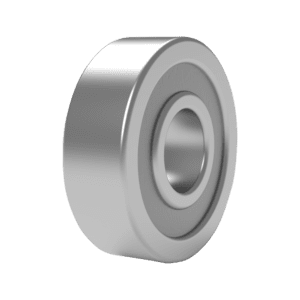

Precision Ball Bearings are the next type of bearing that you might be using. If you have a ball bearing within the wheel, then you have two separate ball bearings on each side of the wheel. Like Roller Bearings, you press in Precision Ball Bearings. The difference is Precision Ball Bearings are sealed and ready to go after they are installed. You will not need to grease them as they are maintenance free. Caster Concepts will always have a seal unless the end user specifies that they do not want them sealed.

Precision Ball Bearings are the next type of bearing that you might be using. If you have a ball bearing within the wheel, then you have two separate ball bearings on each side of the wheel. Like Roller Bearings, you press in Precision Ball Bearings. The difference is Precision Ball Bearings are sealed and ready to go after they are installed. You will not need to grease them as they are maintenance free. Caster Concepts will always have a seal unless the end user specifies that they do not want them sealed.

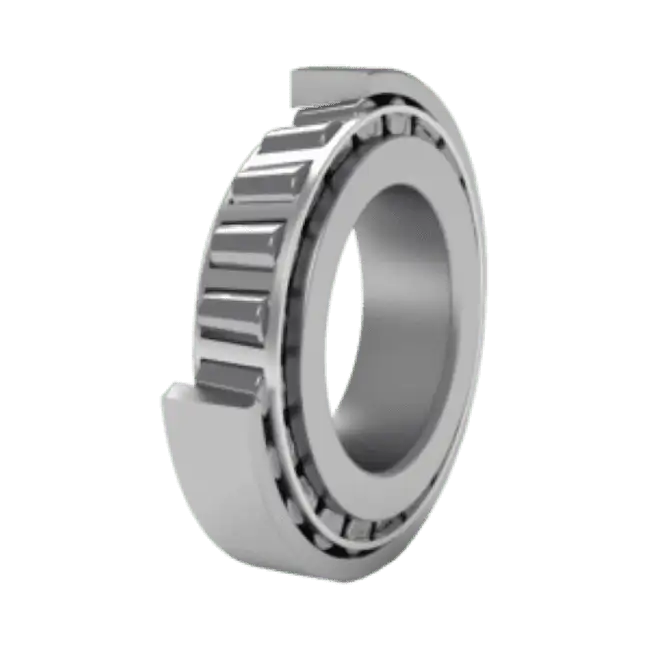

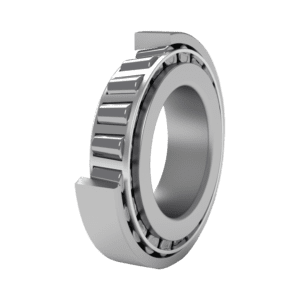

Tapered Bearings come as a two-piece assembly. They have a cone and a matching cup pressed on each side of the wheel core. The cup section of the bearing will look more or less like a large ring of metal. The bearing’s cone section will have rollers going vertically around the cup of the bearing. Tapered Bearings are offset. When looking down on them, you will see the taper.

Tapered Bearings come as a two-piece assembly. They have a cone and a matching cup pressed on each side of the wheel core. The cup section of the bearing will look more or less like a large ring of metal. The bearing’s cone section will have rollers going vertically around the cup of the bearing. Tapered Bearings are offset. When looking down on them, you will see the taper.

The cup section of the bearing gets pressed into the wheel core first, followed by the cone. The cone and cup must press together completely to ensure your bearings do not wear prematurely. This allows the bearing to better handle applications with any side loading pressure on it. These bearings work great in tugged applications or when a forklift is involved.

Once you’ve pressed the bearings into the wheel and added grease, you are ready to check the preload on the bearings.

Put the axle bolt through the wheel and tighten it down until the wheel can no longer rotate or move by gently pushing it with your hand.

After tightening down the axle bolt, you will want to hand loosen until you can rotate the wheel between one-half (1/2) and one complete revolution. Once that’s accomplished, the bearings will have been properly preloaded and ready for use.

For specific applications that are abusive or are in an extreme environment, you should always consult a sales rep to make sure these guidelines would be best for you.