“What is the best caster placement for my cart?” is a question that we get quite often. And for good reason. There are pros and cons of using different caster configurations on carts, and the right setup can make a huge difference in how your cart performs.

To help you with this, I’ve listed below the five main caster setups and the benefits and drawbacks of each configuration. Hopefully, when you are deciding on which configuration will work best at your company, this information will help.

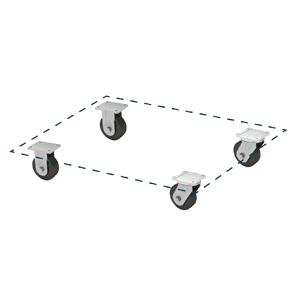

Caster configuration: 4-wheel caster steer

This is a very common setup when thinking about a caster configuration for your cart. I would say I see this about 75-85% of the time. While this configuration is ideal for most carts, it does not necessarily give you the best push/pull forces when measured. However, when you break down the numbers with the right casters, this configuration can be very successful in achieving great push-pull force numbers.

Main users: Automotive industry, Appliance manufacturers.

Benefit: This configuration turns easily and tracks very well when towed. It’s the most popular configuration for casters on carts and trucks.

Drawback: The cart cannot freely move in any direction. To make a 90° turn, the cart must be pulled around on a pivot of the rigid casters.

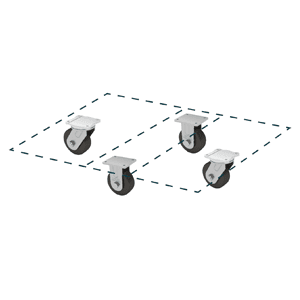

Caster configuration: Two rigid casters in back and two swivel casters in front.

This configuration — although not as common — is highly effective when working in tight spaces. As stated below, these carts will turn in a very tight space. This cart configuration is highly maneuverable and will rotate in its own length.

Benefit: This allows the maneuverability of the tilt-type cart but allows for the tilt action to be eliminated and heavier loads to be carried.

Drawback: This configuration is more expensive than the standard diamond pattern with four rigid casters.

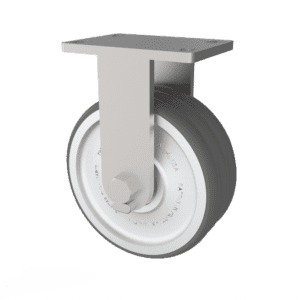

Rigid Caster |

Swivel Caster |

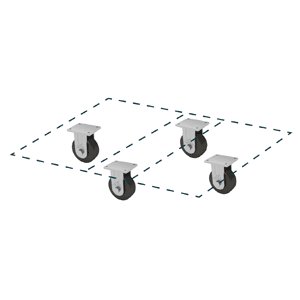

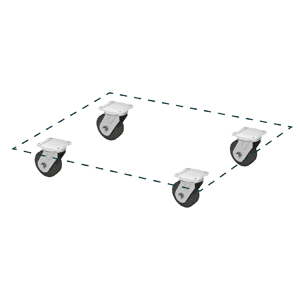

Caster configuration: 4-wheel diamond pattern rigid

Four rigid casters are set in a diamond pattern. Used on tilt-type cart configurations.

Benefit: This is the lowest-cost configuration for carts and trucks. It can also pivot on the center wheels to turn or do complete 360° rotations.

Drawback: It cannot carry heavy loads because only three casters are in contact with the floor at one time (tilt-type cart), and it cannot be pushed sideways.

Caster configuration: 4-wheel non tilt

I rarely see this configuration in the field. I would not recommend this setup unless you are on a tight budget.

This configuration puts four swivel casters at the corners of the cart.

Benefit: The cart can be moved in any direction without the need for turning around.

Drawback: The cart can be hard to control when moving in a straight line. Easy fix: Equip the casters with swivel locks.

An easy fix is equipping the industrial casters with swivel locks. Then when the cart needs to be moved or towed in a straight line, the rear casters can be locked.

Caster configuration: 6-wheel non tilt

As stated in the summary, this setup with the tilting center wheels is a great way to move heavy loads with minimum push/pull force. It is not a fit for all heavy loads, but if you can get away with this, it is a setup that’s highly recommended.

Similar to the 4-wheel diamond caster patterns but can carry heavier loads. It’s also better suited for very long carts.

This caster pattern allows the cart to turn in its own length. The cart style can either turn by tilt type or non-tilt for even greater load capacity.

Main Users: Tire manufacturing, Heavy equipment manufacturing.

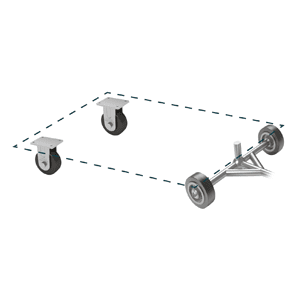

Caster configuration: Wagon type

Two rigid casters in the rear of the cart with two axle-mounted wheels in the front of the cart.

Benefit: This configuration is ideal for heavy loads and is usually power-drawn.

Drawback: This type of cart is not easily maneuvered when operated manually.

The caster configuration, along with the right swivel section and wheel, can make for amazing results when it comes to ergonomics. Knowing the pros and cons of different caster configurations are great information to start you in the right direction.

One final note: Testing shows that if you can use the tilt 4 or 6 caster setup, you will receive lower push-pull forces than all the other setups.

We know that this configuration isn’t possible for all applications. If you are having issues with your push-pull forces, please contact a material handling professional at Caster Concepts who can help you determine the best caster for your application.