Dependable and durable equipment is essential in the manufacturing and assembly of large-scale outdoor equipment like dozers and road-building equipment. Ensuring safety in workflow optimization becomes more necessary when you consider that the carts—and the casters that move them—bear the weight of immense loads.

To facilitate the smooth functioning of assembly lines safely and efficiently, Caster Concepts manufactures heavy equipment casters that can be found both on the factory floor and wherever robust and trustworthy casters are needed.

When moving through the assembly line, large equipment pose significant challenges in terms of maneuverability due to their substantial dimensions, weight, and complex configuration. Casters offer several advantages when it comes to transporting large outdoor equipment through the production process, such as:

Enhanced Maneuverability

Enhanced ManeuverabilityCaster wheels provide excellent maneuverability, allowing the carts that move these machines to navigate tight spaces and sharp turns with ease while also offering excellent tracking abilities and multi-directional movement.

The key factor enabling multi-directional movement is the swivel mechanism incorporated in caster wheels. Swivel casters consist of a mounting plate attached to the underside of the equipment, which is connected to a swivel assembly. The swivel assembly consists of a vertical kingpin or ball race surrounded by ball bearings or roller bearings enclosed within a housing. This design allows the caster to rotate 360 degrees horizontally, enabling movement in any direction.

Check how Caster Concepts helped an agricultural manufacturer solve challenges associated with heavy cart loads.

The manufacturer encountered issues when parts were being dropped onto the carts with significant force and speed.

This abrupt and forceful impact, referred to as shock loading, led to repeated failures of the cart’s existing casters, specifically at two critical areas: the swivel section and the caster legs. It became imperative for them to source a caster capable of withstanding the harsh conditions that these casters encountered daily.

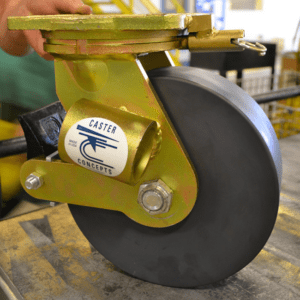

81 Series Caster

The 81 Series swivel casters from Caster Concepts were chosen, along with the matching 80 Series rigid casters. In a 4-wheel configuration, it is recommended to have two fixed casters in the back and two swivel casters in the front.

This arrangement allows the cart to turn easily and track well when being towed. When used together, swivel and rigid casters offer the best combination for carts, providing easy turning while allowing the cart to move in a straight line.

One notable feature of the 81 Series casters is their reinforced bubbled legs. The legs are continuously welded both inside and out to the yoke base, ensuring extra strength and durability. Additionally, the casters have a single-ball race design, which further enhances the strength of their swivel section.

| The 81 Series casters are specifically designed for applications where shock loading is common. They can handle the stresses and impacts associated with such environments, making them a reliable choice for demanding tasks. |

Another option to ensure a safe and secure load is by using a spring-loaded caster. These types of heavy-duty casters are specifically designed to minimize the effects of adverse loading conditions. Spring-loaded or oscillating axles provide a significant advantage by allowing the caster to adapt to changes. The independent movement and flexibility of the axle ensure better contact with the ground, enabling smoother navigation over uneven surfaces, ramps, or obstacles. With enhanced maneuverability, operators can achieve more precise control and effortlessly navigate corners or tight turns.

Another option to ensure a safe and secure load is by using a spring-loaded caster. These types of heavy-duty casters are specifically designed to minimize the effects of adverse loading conditions. Spring-loaded or oscillating axles provide a significant advantage by allowing the caster to adapt to changes. The independent movement and flexibility of the axle ensure better contact with the ground, enabling smoother navigation over uneven surfaces, ramps, or obstacles. With enhanced maneuverability, operators can achieve more precise control and effortlessly navigate corners or tight turns.

The springs in these casters are made of high-strength chrome vanadium, so they last longer even with all the bending and squeezing they go through. The springs start compressing with just 25 pounds of load on each caster, which means your loads will be cushioned. and when they’re not carrying a load, they’ll spring back quietly. Plus, the casters have a long swivel lead that reduces that annoying shimmy and vibration when you’re towing them around.

Outdoor and heavy equipment often needs to be moved around inside the manufacturing facility. Caster wheels are designed to exhibit adaptability to various floor conditions, allowing for smooth and efficient movement across different surfaces. This adaptability is achieved through several key design features and materials.

For example, the choice of wheel material plays a crucial role in adaptability. Caster wheels are made from materials that offer different levels of hardness, resilience, and chemical resistance, enabling them to perform optimally on various floor surfaces.

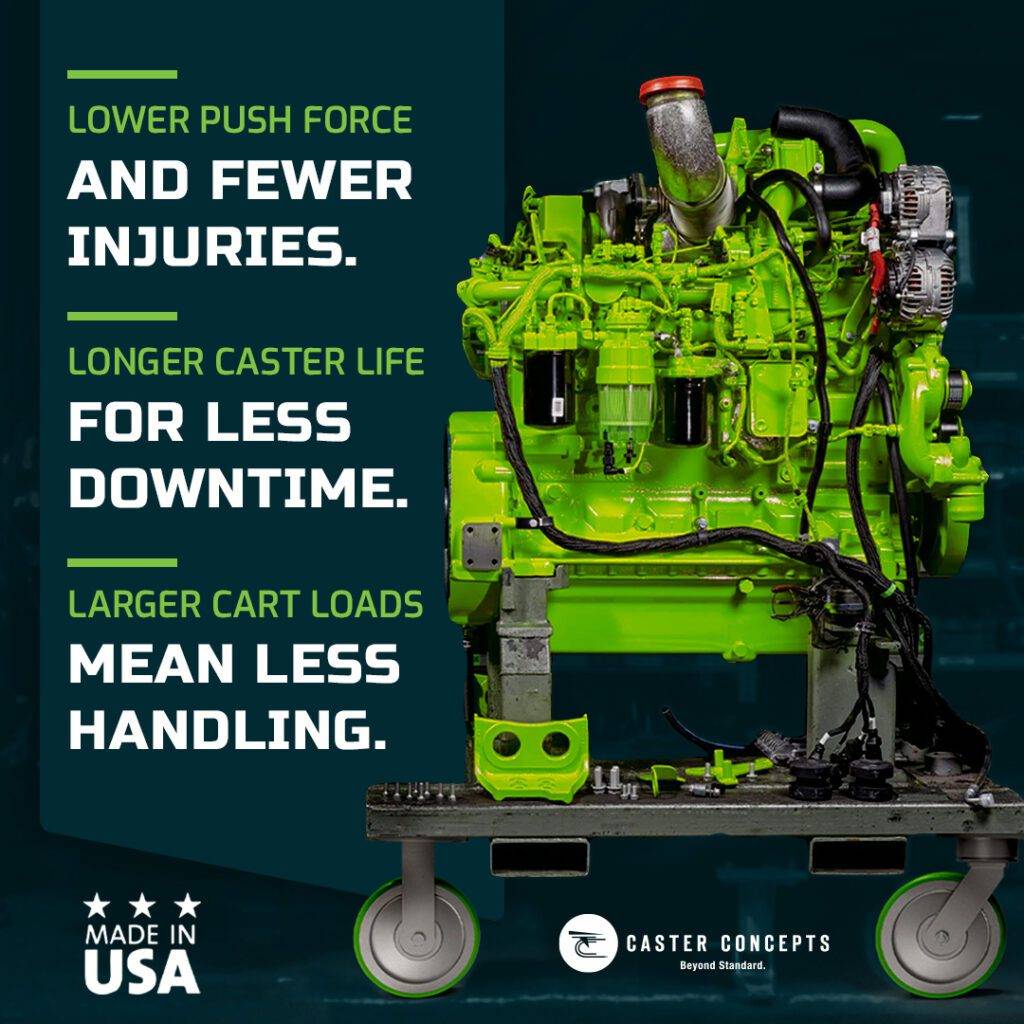

Another common challenge encountered is the increasing weight of loads and wear on casters, which can result in carts becoming excessively heavy and difficult to push. This not only leads to overexertion injuries but also results in substantial losses in productivity and worker compensation claims for companies.

To address this issue, Caster Concepts provides a comprehensive range of ergonomic casters specifically designed to mitigate injuries and minimize the force required to move a cart. These casters incorporate features such as tapered treads, independently rotating wheels, and round wheel designs, all of which work together to reduce both the initial and continuous push force required when moving a cart.

|

By implementing these ergonomic caster solutions from Caster Concepts, manufacturing plants can significantly reduce the risk of injuries, enhance worker safety, and optimize productivity by minimizing the effort required to handle material handling carts.

Caster Concept wheels offer a range of advantages and features that transform the game when assembling large outdoor equipment like tractors, dozers, and construction equipment. From their impressive load-bearing capacity and efficient weight distribution to their multidirectional maneuverability and ease of navigation, Caster Concepts offers heavy equipment casters that excel in any extreme load-related material handling application. Our solutions experts are just a click away.