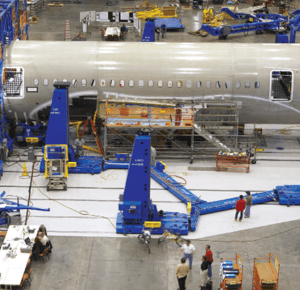

The largest airplane manufacturer in the U.S. was automating its manufacturing process for its fuselage assembly platform. This included converting from tuggers to automated guided vehicles (AGV) to move large work platforms. Each platform weighs 48,000 lbs., and the existing wheels require a push force of about 15% of the total weight. This pushing force significantly impacts the performance of the AGV, reducing speed and battery life.

The company managing the conversion process found Caster Concepts during an online search for improving AGV movement.

The dual-wheel rig required 6 TWERGO® wheels on each caster. Eight custom casters wheels were used on each platform to maximize weight capacity while also optimizing ergonomic performance. This setup improved initial and continuous push force as well as the force required to turn.

Finally, the Caster Concepts engineering team choose spring-loaded, shock-absorbing rigs with a railing around the 12” wheels to minimize risks due to debris on the floor, thresholds, and cracked or uneven flooring.

The final result was a reduction of the initial push force of 15%. The push force was now only 4.5% of the AGV’s total weight, which enabled the AGVs to perform with greater efficiency.