Noise pollution is a significant issue in numerous manufacturing facilities, impacting the health and well-being of employees. Prolonged exposure to high noise levels can cause permanent hearing damage and other detrimental health effects. A leading U.S. automaker, demonstrating a proactive approach to employee safety, acknowledged this concern and addressed it during the construction of their new plant, prioritizing minimal noise production to create a safer working environment for staff members.

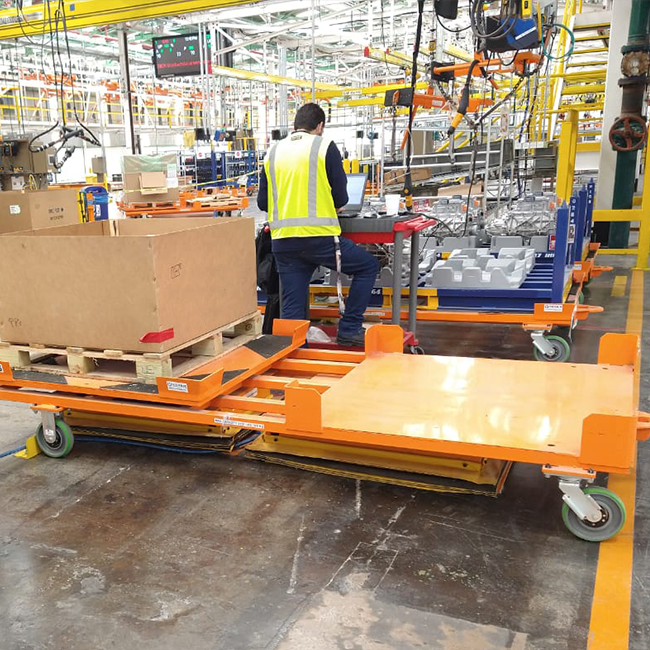

They noticed that their material handling carts produced the highest amount of noise in the facility, so reducing the noise emitted from the carts became their main goal. Noise levels do not compound to create greater noise – the loudest sound supersedes the lower decibel sounds.

CasterShox

To tackle the problem effectively, the manufacturer considered a range of solutions, including using spring-loaded casters, different wheel materials, and various padding techniques. After extensive evaluation, it became clear that CasterShox casters were the most successful in providing a significant solution.

These specially designed casters achieved a notable noise reduction of up to 90%*, significantly decreasing sound levels by up to 15** decibels compared to the other options tested. The OSHA regulation on Workplace Noise 1910.95 states that every increase of 5 decibels reduces employees’ maximum continuous exposure time by 50%. Therefore, a 15-decibel reduction can effectively extend safe work hours for employees by more than six hours, considerably improving their working conditions and overall welfare.

* Based on third-party testing in a client’s production facility, compared against conventional casters.

** Based on in-house testing, compared against conventional casters.

Caster Concepts

16000 W. Michigan Ave

Albion, MI 49224

Office Hours: 8am – 6pm (EST) Mon-Fri

Phone: 888-781-3379