It’s a big notch in the win column when you can lower the cost of repairing a conveyor system made overseas.

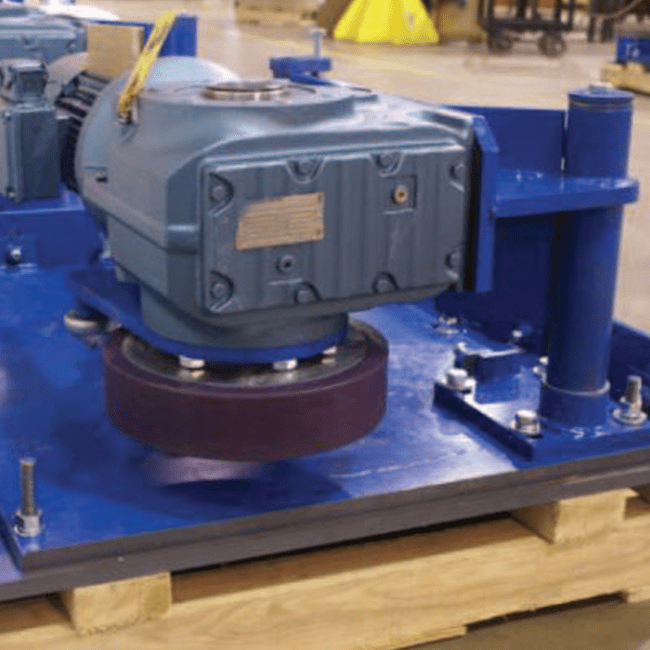

An automotive assembly plant needed a heavy-duty conveyor system repaired. The complicated system was a European design and had a variety of drive wheels, idler wheels, and buffer wheels. So, ordering replacement parts overseas was time-consuming and costly.

The customer needed a reliable domestic source to decrease the cost of replacement parts and provide the parts quickly.

The engineering staff of Caster Concepts reversed engineered and improved numerous components which incorporate polyurethane, fabrication, and precision machining. These components included: full buffer and drive assemblies, spline polyurethane wheel drive wheels, and precision bore key-way wheels that could be urethane coated for steel.

The customer was able to decrease the purchase cost of these components by over 40% while receiving high-quality domestically manufactured parts that exceeded the quality of the OEM replacement parts.