Choosing suitable heavy duty casters for extreme loads outdoor is a complex decision-making process. It involves a solid understanding of several variables, like load capacity, wheel material, and environmental conditions. Considering these technical details, here is an all-inclusive guide to selecting the most suitable casters that cover everything from load weight to terrain type and discuss how they influence the performance of a caster.

Note that the task of moving extreme loads outside is no easy feat. A recent survey revealed that about 60% of workplace accidents related to material handling are due to improper selection and usage of equipment, including casters. When navigating outdoor conditions with heavy loads, the stakes are even higher. Uneven surfaces, temperature fluctuations, and exposure to various elements can introduce often overlooked challenges and lead to meaningful safety hazards and operational inefficiencies.

Casters are specialized wheel assemblies attached to the bottom of objects to enable mobility. They come in various types, each tailored for specific purposes. The two primary types are swivel and rigid casters. Swivel casters can rotate 360 degrees and provide multi-directional movement, making them highly maneuverable. Rigid casters only move in a straight line and are suitable for long, straight paths.

Casters are specialized wheel assemblies attached to the bottom of objects to enable mobility. They come in various types, each tailored for specific purposes. The two primary types are swivel and rigid casters. Swivel casters can rotate 360 degrees and provide multi-directional movement, making them highly maneuverable. Rigid casters only move in a straight line and are suitable for long, straight paths.

Caster modifications include a braking mechanism for locking the wheel in place, and pneumatic casters, which use air-filled tires to absorb shock and handle uneven surfaces. The caster type chosen typically depends on the load capacity required, the kind of surface it will be used on, and the specific mobility needs of the object or equipment.

Outdoor Casters for extreme loads and outdoor environments allow for easy and efficient transportation of objects within various settings, including but not limited to manufacturing plants and warehouses. In particular, heavy-duty casters help support substantial weight, ranging from 2,000 to 50,000 pounds, which is indispensable for material handling equipment. They are available in various styles, materials, and functionalities to meet application requirements.

Best heavy duty outdoor casters differentiate themselves from standard heavy duty casters by their superior load-bearing capacity and construction. They often feature thicker fork legs and a more comprehensive load-bearing swivel section and are attached using a robust steel plate.

Depending on needs, some heavy duty casters are intended to absorb forces when moving at higher speeds, exceeding the standard walking speed. They find their applications in diverse fields, such as the aerospace industry, for moving large workpieces, assemblies, and equipment, including aircraft engine stands and tow bars.

Container casters, a variant of heavy-duty casters, help mobilize loaded or unloaded shipping containers. Moreover, heavy duty casters have altered the manufacturing plants producing heavy machinery and enabled easy and safe movement of heavy parts and assemblies. Dollies and platform trucks, essential material-handling equipment, rely profoundly on these casters.

Now, let’s discuss the factors to consider when choosing heavy-duty casters for outdoor applications.

The appropriate wheel grip is fundamental when selecting casters for extreme loads outside. One might consider pneumatic or solid pneumatic wheels to ensure optimal grip, particularly on outdoor surfaces. These types of wheels feature a vigorous design that allows for excellent shock absorption and an ability to navigate over uneven surfaces smoothly. In addition, the tread design also considerably impacts the wheel’s grip. For instance, ribbed or knobby treads can increase traction, predominantly on loose surfaces like gravel or dirt.

The appropriate wheel grip is fundamental when selecting casters for extreme loads outside. One might consider pneumatic or solid pneumatic wheels to ensure optimal grip, particularly on outdoor surfaces. These types of wheels feature a vigorous design that allows for excellent shock absorption and an ability to navigate over uneven surfaces smoothly. In addition, the tread design also considerably impacts the wheel’s grip. For instance, ribbed or knobby treads can increase traction, predominantly on loose surfaces like gravel or dirt.

Given the variability of outdoor surfaces, the evenness of the terrain is critical to consider. Uneven terrains require specific caster designs to maintain stability and smooth operation. Oscillating axle casters, for instance, can adjust to surface irregularities, maintain wheel contact, and ensure better weight distribution. Similarly, spring-loaded casters can absorb shocks and vibrations caused by uneven terrains while reducing potential damage to the load.

Weather conditions can greatly impact the performance of casters. Factors like temperature, humidity, and exposure to elements such as water, ice, or salt can degrade the material and performance of casters over time. Therefore, selecting wheel materials and coatings that can resist these environmental factors is essential. For example, polyurethane wheels are known for resisting water, oil, and most solvents, which are ideal for wet conditions. Likewise, stainless steel or zinc coatings can provide protection against corrosion caused by exposure to moisture or salt.

When choosing casters for extreme loads, understanding the total load capacity of your caster assembly is critical. It includes the weight of the object being moved and the importance of the trolley or device to which the casters are attached. Note that the load capacity of a caster is not simply the sum of its wheel capacities. Factors such as wheel size, number of wheels, and caster configuration (fixed vs. swivel) are crucial in determining the total load capacity. For instance, dual-wheel casters can double the load capacity compared to single-wheel configurations and offer a lower overall height.

When choosing casters for extreme loads, understanding the total load capacity of your caster assembly is critical. It includes the weight of the object being moved and the importance of the trolley or device to which the casters are attached. Note that the load capacity of a caster is not simply the sum of its wheel capacities. Factors such as wheel size, number of wheels, and caster configuration (fixed vs. swivel) are crucial in determining the total load capacity. For instance, dual-wheel casters can double the load capacity compared to single-wheel configurations and offer a lower overall height.

The swivel or turning radius refers to the space a caster requires to pivot or turn. A larger swivel radius is often preferred for heavy-duty casters outside because they require less force to change direction. Nevertheless, remember that these casters also need more space to maneuver. For example, casters with a larger swivel radius would provide easier maneuverability in a shipyard, where large and bulky loads must be moved.

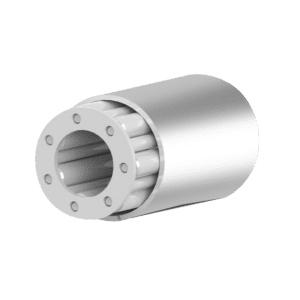

Straight Roller Bearing

The bearing type also expressively affects how much load a caster can bear and how smoothly it can move. Roller bearings are suitable for heavy loads and outdoor use due to their robustness. On the other hand, ball bearings allow for easier swiveling and rolling but may not be suitable for casters for extreme loads. For instance, casters with roller bearings might be a more efficient choice in an industrial setting where heavy machinery is frequently moved.

Lastly, maneuvering the load effectively is essential, especially in constrained outdoor environments. Swivel casters offer greater flexibility and ease of movement than their fixed counterparts. For precise steering control under heavy loads, consider swivel lock or kingpinless caster designs. The latter has been reported to meaningfully reduce swivel head failure rates in the case of heavy-duty casters. Also, the arrangement of the casters on the device, like the diamond or rectangular configuration, can influence the ease of maneuvering the load.

The safety of personnel and equipment is paramount when choosing casters for extreme loads. To ensure safety, there are several guidelines to follow. As mentioned in the previous section, provide the casters’ weight capacity exceeds the load they will carry. For instance, if a load weighs 5000 lbs., casters weighing 6000 lbs. or more should be used. Especially in outdoor conditions where the terrain may not be even, there will be times when only three of the four wheels will be touching the ground, and they must be able to support the load.

RELATED: How is weight capacity determined for casters?

Appropriate caster material should be selected considering the surface type. For example, more robust materials like cast iron or forged steel are preferable on uneven outdoor surfaces. Additionally, larger caster wheels are recommended for heavier loads since they distribute weight more evenly, minimize wheel deformation, and enhance maneuverability.

Regular maintenance and performance checks also ensure the safety and longevity of casters for extreme loads. Systematic visual inspections are a simple yet effective preventative measure for signs of wear, such as cracked wheels, bent brackets, or loose bolts.

Perform routine tests to measure rolling resistance, swivel lead, and ease of movement. Remember, even the best heavy duty outdoor casters can falter under continuous heavy-duty use. Hence maintaining a lubrication schedule is vital for bearings that reduce friction and prevent premature wear. Finally, the load distribution must be regularly checked and adjusted, if needed, to avoid any potential tipping of the equipment. These steps can effectively manage the risk of casters for extreme loads.

RELATED: Caster Maintenance and Care.

As experts in heavy-duty casters, we provide a broad selection suitable for various applications and extreme conditions. Please visit our homepage for more information, and feel free to contact us for professional advice.