Navigating the intricacies of industrial equipment may seem daunting, especially for pivotal components like casters. This article aims to delineate the differences between two widely used types – suspension casters and spring-loaded casters.

Selecting the appropriate caster is paramount in engineering or industrial contexts. Factors such as shock absorption, vibration dampening, load stability, and situational considerations must be carefully weighed to ensure you have the correct caster.

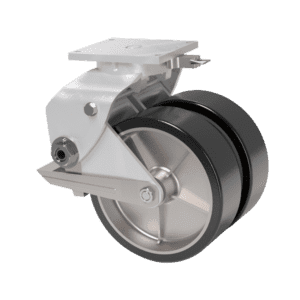

MS Suspension Caster

Suspension casters, primarily utilized in the industrial sector, are specifically engineered to provide an independent suspension system. This system plays a vital role in reducing shock and vibration while transporting heavy loads, enhancing overall performance, and extending the lifespan of your equipment.

These casters are widely recognized for their spring deflection capabilities. This unique feature allows them to absorb shock effectively, ensuring the smooth movement of loaded equipment, particularly on uneven terrains.

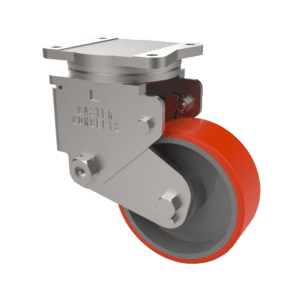

Spring-loaded casters are a go-to choice for businesses seeking to enhance operational efficiency and minimize potential damage to their valuable equipment.

83 Series Spring Loaded Casters

Choosing the correct caster for your industrial needs involves understanding the nuances and differences between the two, such as shock absorption, vibration-dampening capabilities, load stability, and ideal usage situations.

When it comes to shock absorption, both suspension and spring-loaded casters shine, but with varying mechanisms.

Suspension casters use an independent suspension system to reduce shock during transport. Conversely, spring-loaded casters employ spring deflection, providing a smooth, shock-absorbent ride, especially beneficial over uneven terrains.

Related: Shock Absorption Casters with Unparalleled Noise Reduction

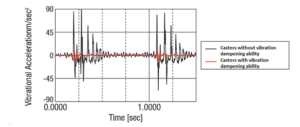

In terms of vibration dampening, suspension casters come out on top. The independent suspension system significantly lessens vibration, ensuring a more stable and smoother ride. While spring-loaded casters dampen vibrations, they might be less efficient than their suspension counterparts in continuous and high-level vibrations.

The vibration-dampening ability of suspension casters also prevents static electricity from generating on the floor with antistatic wheels.

Related: Good Vibrations? Shock-Absorbing Casters Are Ideal For Many Industrial Applications.

Load stability, a key consideration in any caster application, can be influenced by the caster type. With their suspension system, suspension casters ensure a stable load bearing, especially during movement and under dynamic loads.

Though providing good load stability, spring-loaded casters may be slightly less effective when handling heavy, dynamic loads.

Ultimately, the choice between suspension and spring-loaded casters depends on the specifics of the application.

However, they are almost the same but have slightly different functionalities.

Suspension casters would be more beneficial for environments with significant shock and vibration. However, heavy duty spring loaded casters can be a superior choice for uneven terrain applications requiring effective shock absorption.

By understanding these characteristics and considering the specific needs of your operation, you can choose the most suitable caster for your project.

A few key factors can guide your decision-making when choosing between suspension and spring-loaded casters for your industrial needs. These considerations help you select a caster that enhances operational efficiency and safeguards your equipment and workers.

Load weight is one of the primary factors. It’s essential to consider the total capacity of the caster, as being within the safe operating zone allows you to take advantage of the “sweet spot” or “recommended load capacity.”

Load weight is one of the primary factors. It’s essential to consider the total capacity of the caster, as being within the safe operating zone allows you to take advantage of the “sweet spot” or “recommended load capacity.”

This ensures that your caster can handle the weight of the supporting equipment. By staying in the operating zone, you can maximize the life of your caster and protect it from potential damage or breakage.

RELATED: How Does A Spring Loaded Caster Work?

You need to understand the load capacity of the caster as well as load weight; some casters are rated to handle 500 lbs., while others can have a higher weight limit, such as 20,000 lbs. (super heavy duty casters) or more.

The nature of the terrain also significantly influences caster choice. Spring-loaded casters excel in environments with uneven terrain due to their excellent shock-absorbing capabilities. However, suspension casters provide superior vibration dampening on flat or moderately rough surfaces.

When considering the expected usage frequency, durability comes into play. Suspension casters, known for their robust construction, can withstand high-frequency usage, making them a good choice for round-the-clock operations. Spring-loaded casters, though durable, may wear out more quickly under constant heavy-duty use.

Lastly, your operation’s specific shock absorption and vibration-dampening needs will help determine the correct caster. For settings with continuous and high-level vibrations, the independent suspension system of suspension casters may be more beneficial than a standard shock-absorbing caster.

By considering these factors in your specific context, you can make an informed decision that will positively impact your operation’s overall productivity and safety.

In conclusion, suspension and spring-loaded casters are almost identical but have unique benefits and uses. Suspension casters offer excellent vibration dampening and stability, making them suitable for heavy, dynamic loads.

On the other hand, spring-loaded casters excel in shock absorption and smooth operation over uneven terrains.

Understanding these key differences is crucial for selecting the right caster for your application. This decision can significantly impact your operational efficiency, equipment longevity, and safety.

At Caster Concepts, we’re here to assist you further with your caster needs. Contact us for professional consultation or to order standard or custom-designed casters tailored to your unique requirements.