A common misunderstanding is why different urethane tires have such drastic price differences. For example, a standard urethane 8×2 wheel may cost $30-40/each, while another 8×2 wheel may cost $150/each. As a customer looking at a quote, it can be hard to understand the difference between the two wheels. This blog explains the differences and what drives costs between different urethane tires.

The first step to understanding the cost divide with urethane treaded wheels is understanding some basics about urethanes. A urethane is an elastomer containing a prepolymer and a curative. There are many different prepolymers and curatives, and each helps create a unique urethane (or polyurethane). These attributes include tensile strength, hardness, modulus, split tear, rebound, and compression set.

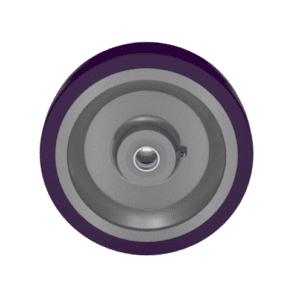

These prepolymers and curatives have different properties that help create these unique urethane systems. For example, our 92A HPPT Poly tread is a high-performance formulation designed to resist heat buildup and carry higher weight capacities for high-speed applications.

These prepolymers and curatives have different properties that help create these unique urethane systems. For example, our 92A HPPT Poly tread is a high-performance formulation designed to resist heat buildup and carry higher weight capacities for high-speed applications.

And as is the case with most things, you pay for what you get. Many less expensive urethane systems will yield a final product with decent properties, providing a solid wheel used on pushcarts and non-demanding applications.

As your application begins to require better dynamic properties from the urethane, the costs do go up. An ergonomic wheel requires a prepolymer that has a higher rebound. Those prepolymer backbones are more expensive to manufacture and will cost more than a “basic” urethane prepolymer. If you have a demanding application with heavier loads and high towing speeds, using tougher urethanes is required that generate less heat. This requires even more expensive raw materials and sometimes even requires a special curative to get the best possible properties out of the system. For example, the cost difference between our standard urethane and our high-performance urethane is six times just on the raw material side. Then the high-performance materials can require special handling or curing cycles which add to the cost.

So when picking out a wheel for your application, know that the cost can vary by 10x or more if you choose a high-performance urethane versus a more standard, less dynamic urethane.