The right wheel makes a huge difference in performance, whether its an automobile, bicycle, or industrial cart, the wheels directly impact performance. When it comes to industrial carts, the wheels have a huge impact on safety, weight capacity, ergonomics, and damage to flooring are arguably the most common factors, but there are others, depending on the application. Therefore, choosing the right wheel for the application is very important.

The first factor to consider is the total weight capacity of your application, including cargo and cart weight. If the wheels cannot support the weight of the load, their other benefits are meaningless. Once the weight capacity is cleared, the environment is the next factor to consider. Environment refers to flooring conditions, temperatures, moisture, and other conditions relevant to where the wheels are used. Ergonomic benefits, such as reduced push-pull force are achievable with certain caster wheels as well.

Here’s a list of the most common industrial caster wheels, with a brief description of their benefits.

Forged Steel Wheels: Achieve the highest weight capacities of any industrial caster wheel, best for withstanding shock loading. While these wheels are generally easier to roll, they are louder than other wheels and have a high risk of damaging flooring.

Cast Iron Wheels: Achieve high weight capacities, about 25% less than steel caster wheels. Cast Iron wheels have a good surface for bonding with polyurethane and are significantly less expensive than steel caster wheels. Cast Iron caster wheels offer the same benefits and challenges as steel caster wheels.

Phenolic Resin Wheels: Weight capacities are similar to Cast Iron wheels, and resist flat spotting when left loaded and in the same position for extended periods. Phenolic resin caster wheels are temperature resistant to 300* and resist grease, gas, and oil.

Mold on Rubber: Softest of all industrial caster wheels, Mold on Rubber wheels are very easy on flooring but are likely to leave marks. They have lower weight capacities, reduce noise when rolling, and are ideal for wet or moist environments.

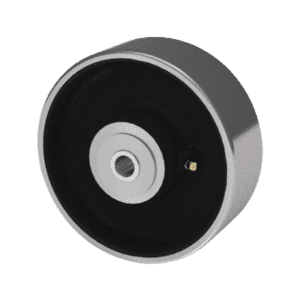

Polyurethane on Cast Iron Wheels: Most common of all industrial caster wheels, have high weight capacities while achieving various benefits through the use of polyurethane tread materials. Polyurethane can offer numerous benefits, depending on the formulation. Benefits include reduced push-pull force, reduced noise, resistance to heat build up, flooring protection, resistance to certain chemicals, and more.

There are additional caster wheels available for industrial applications, they are more specific to applications such as V-Groove wheels, for a complete list of industrial caster wheels, please refer to our wheel configurator tool.