Transporting aerospace and aircraft engine or components safely from indoors to outdoors can be challenging. A great example is a jet aircraft engine stand used in ground support applications within the aerospace industry. It’s a big stand that costs a lot of money, and there are several factors to consider when choosing the proper heavy-duty caster regarding safety and performance.

A Spring Loaded Caster that can cushion sensitive loads from shock and vibration. A heavy duty Pneumatic Wheel helps ensure the safe and secure transportation of loads moving over uneven surfaces indoors and out. And because these engine stands can also be heavy, awkward, and hard to move, a Swivel-on-Swivel design minimizes the strain of maneuvering a heavy engine stand by making it easier to push and turn.

When moving a jet engine on a stand that can cost upwards of $40M, it is important to understand what loads the stand is experiencing and ensure your casters have an appropriate safety factor built in. Caster Concepts designs and tests to ICWM standards, which means there is a 4x static safety factory and a 2x dynamic safety factor.

However, manufacturers are looking for a catalog load rating of four times the anticipated load in many aerospace and aviation applications. This means the actual safety factor is 8x dynamic and 16x static. This is where Caster Concepts’ heavy duty casters come in. Failure is not an option, and the extra cost of purchasing casters with higher safety factors is worth the assurance that the casters will not fail and damage the jet engine.

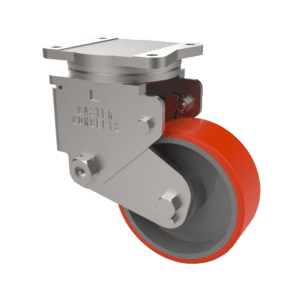

83 Series Spring Loaded Jet Engine Stand Casters

In aerospace and aircraft applications, most engine stands and transport carts use suspension systems due to the terrain they operate on. Uneven surfaces can cause vibrations, affecting load stability and damaging sensitive equipment like jet engines and costly components.

In jack stand operations, shock absorption is necessary for the jack to operate correctly.

When you disengage the jack, the casters move it around. As you operate the jack and apply load, the casters deflect, allowing the jack legs to take over and support the total load. Read our blog, How Does a Spring Loaded Caster Work, for more information on this process.

Aerospace, aircraft, and other industrial settings prefer pneumatic tires for their high load capacity and excellent shock absorption. Although not a true shock-absorbing caster, this benefit still helps to reduce potential damage to delicate items during aircraft engine transportation.

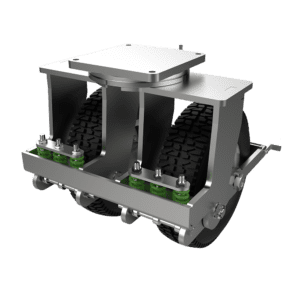

Dual wheel pneumatic spring loaded caster

Besides their shock-absorbing ability, other benefits of using pneumatic caster wheels include:

61 Series Pneumatic Caster – Aircraft engine transportation stand

The towing speed of the aircraft engine transportation stand affects the type of caster wheel required. For speeds under 10 mph, a urethane-treaded wheel is typically used. Consult an engineer to design a urethane wheel for your application, as most catalog ratings are for walking speeds. For tow speeds that are over 10 mph, a pneumatic or solid-pneumatic wheel will have to be used. These wheels can handle higher speeds, but they quickly increase in size to support loads equivalent to urethane wheels.

Sometimes, the engine stand needs some precise movements to get into its final position; a stand can weigh quite a bit, which can make it difficult to move.

We use a Swivel-On-Swivel Caster with swivel locks to maneuver the load and lock for straight-line movement. We can add steering tubes to the swivel casters, enabling the operator to use a lever for precise positioning.

Customers typically ask about safety factors, shock absorption, wheel material, and positioning options when specifying casters for aircraft engine stands. Hopefully, this article helped answer your question and explained what features are typically important. If you do have questions or would like to talk to one of Caster Concept’s Solutions Specialists, please contact us. We are here to help.