A question we get asked often is, “Are your casters designed to any certain standard?” Or, more specifically, “Are your casters designed to ICWM standards?” The answer to that is YES. We design to the Institute of Caster and Wheel Manufacturers’ performance standards. For those in the know, that should be enough. For those that don’t know what ICWM is, we’re happy to offer a short explanation.

The Institute of Caster and Wheel Manufacturers (ICWM) is an industry group within the broader Material Handling Industry (MHI) association. MHI is the nation’s largest association developing resources for material handling, logistics, and supply chain industries. In 1996, ICWM began developing performance standards for casters and wheels for North America. ICWM set testing and performance requirements for casters and wheels approved by the American National Standards Institute (ANSI) in 2004. (Revised in 2012 and 2018). This standard helps manufacturers and customers evaluate the safety, durability, structural integrity, and technical requirements for various groups of casters and wheels.

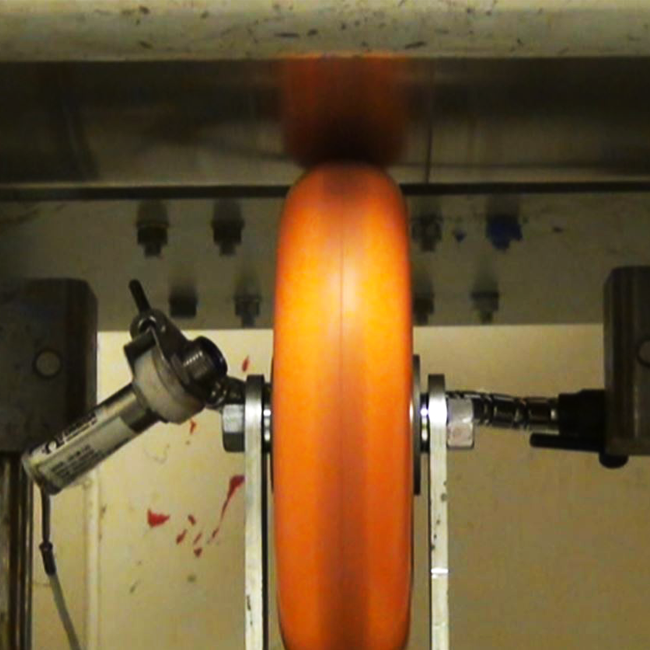

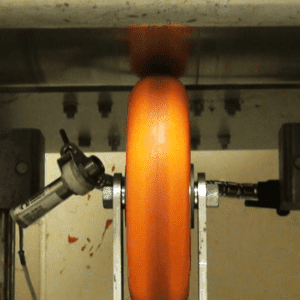

At Caster Concepts, our in-house capabilities enable us to test products to the ICWM standards. One example is a wheel dyno which can have obstructions (Bumps) added. The dyno tests the load capacity of a wheel, and the obstructions simulate a wheel hitting a bump or cracks commonly found on industrial floors. Other equipment in our testing lab includes a static load tester, a hardness tester, and a drop tester. Caster Concepts performs periodic testing of products to ensure high quality and that we meet industry standards. This equipment also allows us to rapidly develop new products as we can test quickly without outsourcing to third-party companies.

At Caster Concepts, our in-house capabilities enable us to test products to the ICWM standards. One example is a wheel dyno which can have obstructions (Bumps) added. The dyno tests the load capacity of a wheel, and the obstructions simulate a wheel hitting a bump or cracks commonly found on industrial floors. Other equipment in our testing lab includes a static load tester, a hardness tester, and a drop tester. Caster Concepts performs periodic testing of products to ensure high quality and that we meet industry standards. This equipment also allows us to rapidly develop new products as we can test quickly without outsourcing to third-party companies.

In addition to industrial standards, Caster Concepts developed a testing device to consistently measure forces a human would exert while pushing a cart at various loads. This testing device allows us to test a wide range of caster types. Evaluating caster performance helps us recommend the best caster style for a customer’s particular application to improve ergonomics and reduce human injuries. As safety standards have become more prevalent around push forces and with the current testing methods having such high variation, this machine has come in handy for completing comparisons and evaluating push forces consistently for our products.

Hopefully, this explanation of ICWM provides more context to the standards that our products and designed and tested around. For more information on the ICWM standards, check out the link below.