83 Series Spring Loaded Casters

Spring loaded casters have long been the gold standard when it comes to reducing noise and protecting payload in the manufacturing environment. When the proper caster and spring configuration are chosen the outcome will be very predictable, while achieving the planned noise reduction. If the spring loaded caster is not properly designed and the spring configuration is not properly engineered the result will be less than desirable and may even increase noise levels in the manufacturing operations.

There are three key considerations that must be evaluated prior to engineering the proper spring loaded caster. To understand these one must first understand these three factors that occur in any spring:

Each and every spring, no matter how small or how large, has a measurable force that must be applied to the spring to initiate deflection of the spring configuration.

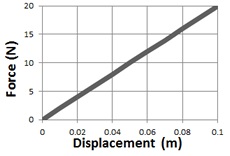

Once the spring begins to deflect it is designed to provide a very predictable deformity of the spring configuration in relation to the amount of force that is applied. This is a linear relationship and is directly proportional, in that X amount of force will result in Y amount of deformity, at every point along the line.

At the endpoint the spring is completely deformed as a response to the force and no further pressure will change the spring unless the pressure is so great that in fact deforms the material that the spring is made of.

Spring displacement is linear until the point of full deflection

Spring displacement is linear until the point of full deflection

When designing and building spring loaded casters each one of these characteristics must be considered to have a spring loaded caster that properly functions. Springs are made with a variety of different characteristics that impact each of the three areas discussed:

In the engineering and manufacturing of the caster, there must be a pre-load applied to the spring. Let’s assume approx 250 lbs of force. At this point, any additional force that is applied to the caster will result in spring deflection and noise reduction. Any load applied to the caster below this pre-load will result in zero deflection.

The spring should function in a similar fashion to the theoretical deflection curve. This means that for each pound of force applied there is a very predictable movement of the spring. There is also an operational sweet spot — that with proper planning and complete understanding of the operation — the spring would ”live in this area” of the graph. If the engineering of spring location and spring alignment is not properly applied to the design, the end result will not be a linear graph and the operation will not be optimal and most likely will lead to damage to the caster, cart, or payload.

The spring should function in a similar fashion to the theoretical deflection curve. This means that for each pound of force applied there is a very predictable movement of the spring. There is also an operational sweet spot — that with proper planning and complete understanding of the operation — the spring would ”live in this area” of the graph. If the engineering of spring location and spring alignment is not properly applied to the design, the end result will not be a linear graph and the operation will not be optimal and most likely will lead to damage to the caster, cart, or payload.

At this point, the caster is no longer a spring loaded caster. The caster functions like a regular caster without any sound-deadening effect. Even in properly engineered casters this can happen with shock loading of the cart, overloading of the cart, or hitting an obstruction or pothole during operation. If the process of ”bottoming out” occurs frequently during the normal operation, most likely the caster is not properly designed for the application.

All of these characteristics are taken into consideration when spring loaded casters are specified or designed by the Caster Concepts engineering team.. Communication between the end user and the engineer is the key to designing a product that meets all the needs of the application while having an extended product life-cycle.