You’ll often find pneumatic tires used on material handling carts due to their many benefits in industrial caster applications. They have both pros and cons, but their main advantage is the ability to absorb shock loads from impacts and cushion the load.

Pneumatic wheels consist of a metal hub with a rubber tire mounted to it. The tire is filled with air or foam to the desired pressure level to achieve the appropriate load and deflection characteristics.

Besides their shock-absorbing ability, other benefits of using pneumatic caster wheels include:

Pneumatic tires are preferred in industrial and warehouse settings because of their high load capacities and shock-absorption qualities. Although not a true shock-absorbing caster, this benefit still helps to reduce potential damage to delicate items during transportation.

Pneumatic tires are preferred in industrial and warehouse settings because of their high load capacities and shock-absorption qualities. Although not a true shock-absorbing caster, this benefit still helps to reduce potential damage to delicate items during transportation.

Pneumatic caster wheels are commonly used outdoors on uneven surfaces, whether on a runway or an off-road vehicle. They offer a smoother ride than their solid counterparts.

Medical equipment like stretchers and wheelchairs utilize pneumatic casters. They provide patients with a comfortable and less jolting experience. Their noise reduction capabilities also enhance their worth in such settings.

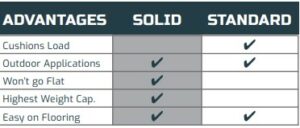

Semi-pneumatic wheels (Solid) are another option when considering this wheel type. Where there isn’t much difference in outward appearance, inside, they are much different.

Semi-Pneumatic wheels feature a dense, molded rubber and are considered a solid pneumatic wheel. Since they aren’t filled with air, they aren’t pressurized and won’t go flat.

Adding polyurethane into the mix can be a cost-effective choice under the right circumstances, especially in indoor applications. Pneumatic casters are still the best choice for loads that need to move outdoors or over imperfections in flooring. They provide better traction, a smoother ride, and less friction than their counterparts, even when the terrain is bumpy and rough.

Adding polyurethane into the mix can be a cost-effective choice under the right circumstances, especially in indoor applications. Pneumatic casters are still the best choice for loads that need to move outdoors or over imperfections in flooring. They provide better traction, a smoother ride, and less friction than their counterparts, even when the terrain is bumpy and rough.

Polyurethane casters have one huge benefit over their pneumatic counterparts: load capacity. For example, if a caster must have a capacity of 5000 pounds, the polyurethane caster to support such a weight would be much smaller than a pneumatic caster with the same capacity.

In short, pneumatic tires can provide great benefits, such as shock absorption and the ability to go off-road. The drawbacks are that they are a little harder to get moving, and their extended leads also present an increased chance of flutter.

Another option for loads where precise movement is required and the load can’t be moved manually by a single operator, Conceptual Innovation’s motor-powered Drive Caster® simplifies the process while reducing the risk of injury and associate costs to improve productivity.

There are many benefits of pneumatic tires, but it is always a good idea to talk to a Caster Concepts movement solutions expert to help you determine the best caster wheel for your application. You can reach us by calling 888-799-7166, contacting us through email, or using the chat now button. Let’s get rolling!