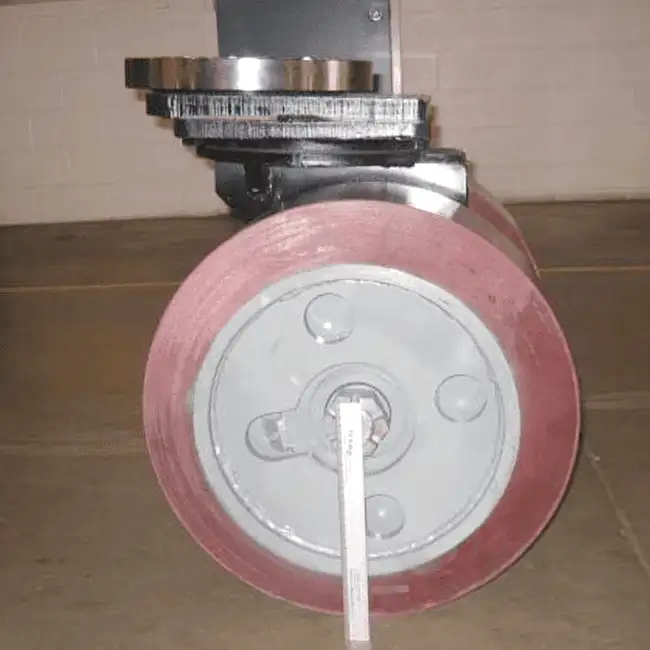

Nearly 70 percent of heavy-duty industrial casters are manufactured with a polyurethane tired wheel. Due to this high usage in industrial casters, there are many advantages of high profile polyurethane wheels.

The most common polyurethane wheel tread is approximately 0.375 inches thick, which is considered a standard wheel tread, and used in various heavy-duty applications.

However, if your application requires greater carrying capacity, wearability, or sound deadening, a high profile treaded wheel, which is generally 1.25 to 1.75 inches thick, is a great alternative. Caster Concepts Inc. engineers can help you choose the best option based on the considerations below.

Carrying Capacity: The most common reason to increase the thickness of polyurethane wheels is to up carrying capacity without changing wheel size. For instance, a thin tread wheel of 8 by 3 inches in size carries 2000 pounds. The 8 by 3 inch, high profile tread would carry 2500 pounds, roughly a 25 percent increase. This increase is fairly consistent no matter the wheel size being compared.

Greater Wearability: Some difficult applications require overloading wheels and skidding with forklifts while under loads. Thicker polyurethane wheels can extend the life of these products. Heavily loading thin tread wheels and then skidding under load will likely cause flat spots very quickly, and inoperability.

It’s important to note that high profile polyurethane wheels used at near capacity loads in powered applications, without adequate dwell time, are not a good application. In these cases, reconsider thin wheels. When designing a thick tread polyurethane wheel, one must be very careful if speeds are greater than 3.5 mph for extended periods during the heavy-duty application. During controlled testing, Caster Concepts Inc. engineers have proven that high profile wheels have a greater heat generation curve, and hence premature failure.

Sound Deadening: Thicker polyurethane wheels increase sound deadening. The harder the urethane used, the more minimal the deadening. For instance, if the urethane is harder than 95 Shore A, the sound deadening is limited, but when the urethane is 90 Shore A or less, significant deadening occurs. One could expect a 3 to 5 decibel decrease in noise using 85 Shore A material.

At Caster Concepts Inc. our engineers we will work with you to help you find the polyurethane wheels that best fits your needs.