Why do shopping cart wheels wobble?

Besides being extremely irritating, the result of caster flutter has many negative effects. In industrial applications, caster flutter results when a swivel caster is harmonically excited. This causes the heavy duty caster to swing uncontrollably from side to side as the wheel rolls forward. In this case, caster flutter is more than annoying: it results in excessive noise and increased wear on all bearing elements. It can also result in loss of tracking and control of the dolly or cart, which could cause a serious accident if the cart tips over.

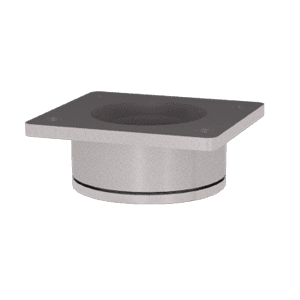

Of all the factors that can cause this problem, these three are the most common: Caster Swivel Section A Sloppy Swivel Section – If the swivel section is too loose, it can cause the caster to flutter uncontrollably. A loose swivel section, no matter the diameter of the raceway, will create resonance leading to flutter. Misalignment of the Caster to the Ground – If the caster is mounted incorrectly or the caster legs are bent, a resulting misalignment will cause the caster to flutter. Moving at High Speeds – At high speeds, a caster will flutter once it hits a certain velocity and is excited at its natural frequency. In most applications involving industrial casters and wheels, the wheel is not balanced and lends itself to fluttering. |

There are steps you can take to minimize the occurrence of caster flutter. From increasing swivel lead and wheel composition to moving at slower speeds, these options are the best ways to control the situation.

The engineering staff at Caster Concepts, Inc has extensive knowledge of fluttering issues of industrial casters. If you are looking for effective and cost-efficient ways to correct caster flutter, please get in touch with us. We can help!

Need Immediate Assistance?Phone: 888-781-1470 |