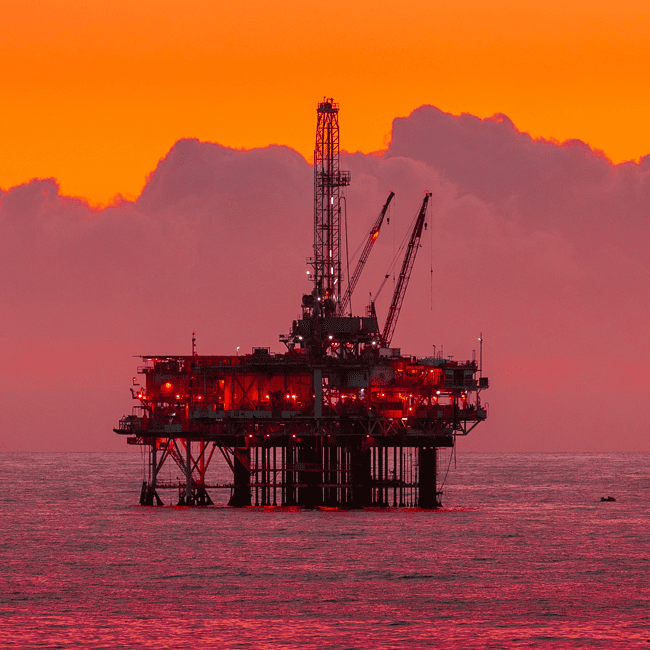

A significant energy transition company accepted a contract to work on compressors located on an oil rig in the Atlantic Ocean. This unique application required moving large compressors weighing 38,000 pounds each. At these weights and conditions, implementing additional safety factors was necessary. These special considerations also required shock-resistant, swivel lock casters from Caster Concepts to meet these requirements.

The giant compressors and their components were mounted on carts. They were winched and guided down a channel iron pathway on concrete decking. To ensure safe operation and follow safety guidelines, the casters must handle weights three times the expected load. Locking the compressor carts down while moving by crane was also a requirement.

91 Series Caster

The customer needed a shock-resistant caster with a swivel lock. The solution was Caster Concepts’ 91 series 12 x 4 Heavy-Duty Polyurethane casters with locks and brakes. While the casters didn’t have to be corrosion-resistant, the 91 series comes standard with a powder coating that is resistant to rust and is great for this application where salt water is prevalent.

The 91 Extra Heavy Duty Caster was chosen due to its superior strength and is a popular choice where shock loading is present. Since these carts are often lifted via a crane that connects to the compressors, the casters needed to be able to take the punishment of being lowered to the ground with a heavy load. The 91 Series also features a sealed swivel section to prevent moisture intrusion. Due to debris such as nuts and bolts on the deck, a T/R 95 poly tread was chosen because of its high tear resistance and extended wear.

The customer moved the casters quickly on their concrete decking, and the casters are performing well and handling the shock from being picked up and moved by the crane. The customers also liked the option of swivel locks, which enabled them to maneuver the compressors into place. Adding the brakes was also important, as it kept the compressor from rolling while being worked on. And when you are in the middle of the ocean, a 20-ton compressor rolling around is not an option!