A manufacturer of capital equipment for the wood products industry was having difficulty with a cart application due to its weight.

As you can imagine, some of the equipment used in a large sawmill has a large footprint. In this case, the company was loading machinery on a cart that weighed more than 12,000 lbs., requiring up to 4 employees to move the cart manually.

At this weight, overexertion injuries were becoming common, and a solution needed to be found quickly.

The company had tried using an option of a heavy-duty standard poly wheel, but this option proved to provide minimal success at best.

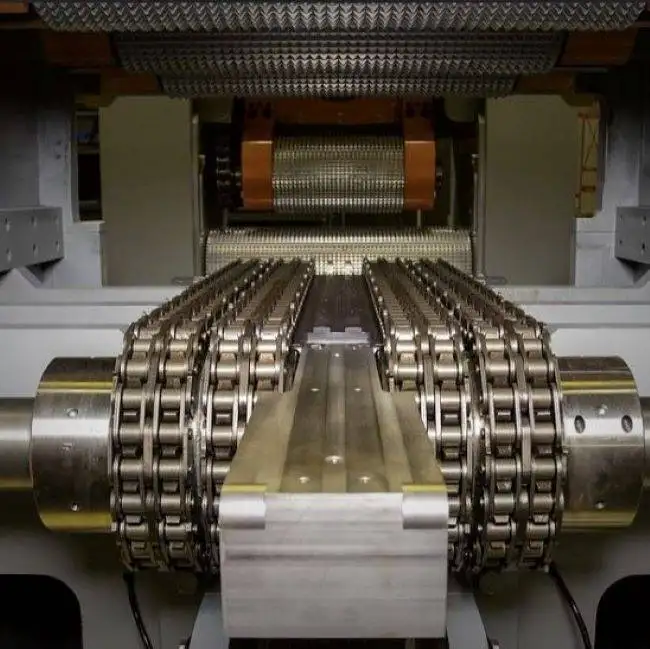

91 Series Caster

After consulting with Caster Concepts, the company switched to a 91 series caster with a 8×3 Nylatron wheel. The 91 caster rig features a swivel section that puts the ball bearing in a sheer load, providing great strength and smooth operation when swiveling in a loaded state. The nylon wheel provides weight capacities close to a similar size cast iron or steel wheel, and the vibration-dampening material actually offers a quieter operation. Additionally, the precision ball bearings used in the caster offered better rollability, which improved ergonomics.

Upon installation of the 91 Series rig with Nylatron wheels and precision sealed ball bearings, the customer was able to move the cart 75% loaded, or 9,000 lbs., with a single person. The company has since placed orders for this caster setup on two additional applications.