A Tesla plant needed to safely transport a 6,500 lb. roll of material from the staging area into the production line. The company decided against cranes due to the increased risk of injuries from lifting heavy loads at higher heights.

Once the cart was at the production line, it had to be aligned precisely with the feeding machine. This required raising the roll to a predetermined height. The feeding machine would then lock on to the ends of the roll, allowing the cart to retract the arms and be driven out of the load position.

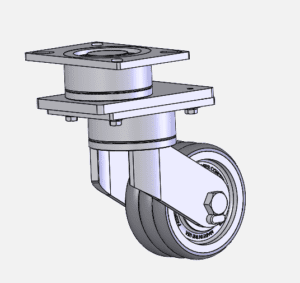

154 Series Swivel-On-Swivel Caster with Twergo Wheels

Working closely with the customer, Conceptual Innovations designed a retrofittable motorized drive lift system. The drive system featured a hydraulic system to lift and lower the side arms of the drive cart to align the roll at the proper height. Individual drive caster power the cart for increased maneuverability.

Twergo 3-Wheel Design

Swivel-on-Swivel Casters from Caster Concepts were also incorporated into the cart. Each Swivel-On-Swivel Caster consists of two stacked 77 Series Swivel Casters with sealed dual-row ball bearings for high precision and maintenance-free performance.

The Twergo® Wheels feature a tapered tread and independently rolling wheels. The unique design of the Twergo wheels makes them easier to move and turn, which means less power is needed to move the cart. The TR95 tread on the caster wheels has a high elasticity and high tear resistance, which helps increase the longevity of the polyurethane wheel.

Tesla received a motorized cart system with increased maneuverability and lifting capabilities while negating the need for an overhead lifting system. These benefits reduced the time and labor it took to position the material into production. This also eliminated the possibility of injury associated with using an overhead crane.

We engineer material handling systems to maximize your productivity and reduce costs. For more information: