A large automotive manufacturer was having issues moving carts. Each cart needed over 60 lbs of initial push force to get moving. This put many cart operators at risk for overexertion injuries. Adding to the problem was moving the heavy carts into work cells. This required some tight maneuvering. In addition, the carts were equipped with turntables that were hard to move, thus adding to the overexertion problem.

Incorporating Swivel-on-Swivel Casters with Twergo wheels reduced initial push force below 45 lbs. At that push force rate, close to 90% of the population was now within safe limits, significantly reducing the number of workers at risk for a potentially costly injury. A big benefit of using Twergo wheels is that they offer a lower coefficient of friction and good abrasion resistance.

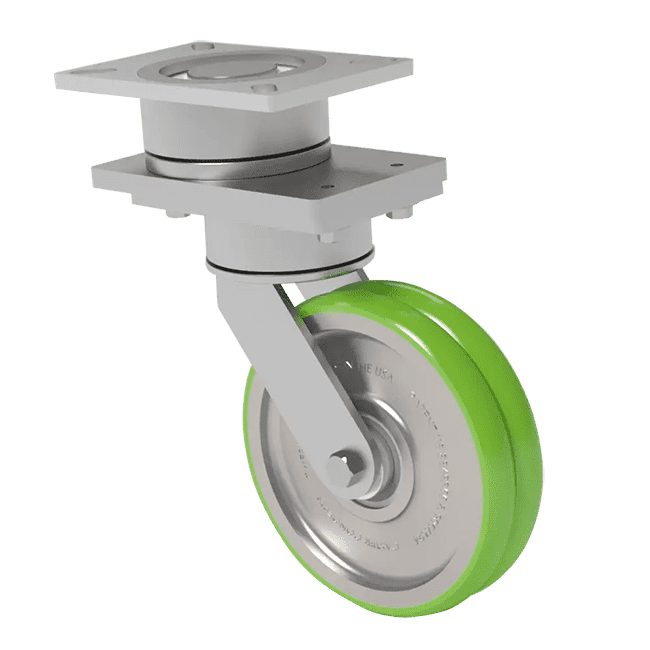

A swivel section is great for reducing initial push force when all of the wheels are not aligned, or parallel. This misalignment results in an additional force being required to start rolling the cart. The dual swivel section reduces initial push force in this situation because the swivel lead is greater on the dual swivel section caster compared to a conventional swivel caster.

The dual swivel section caster also virtually eliminates swaying, a benefit for applications that require a lot of maneuvering, lining up, or fitting into tight spaces.

In addition, the Drive Caster Trike was able to easily maneuver the carts into the cells, a tight space that traditional motorized vehicles were having difficultly moving in. Inverting Twergo wheels under the turntables also made the turntables on the carts significantly easier to move and turn. Because of these improvements, costly employee injuries went down, which also helped the company realize a faster return on investment.