What do ergonomic industrial caster wheels really mean in the big picture of workplace productivity, safety, and cost savings? First, let’s take a minute of all that is involved in moving a material handling cart.

The skeletal structure of the human body is composed of three rigid body segments that are moveable at 27 different joints. In play are the elbow, shoulder, wrist, and hand as well as your hip, knee, and ankle. In short, there is a lot going on in the process of pushing or pulling a load.

The muscles in your body are also reacting to the forces of a load you are pushing. This exertion can overtax a muscle group if the weight is not properly distributed. It’s no surprise that manual material handling (MMH) work contributes to a large percentage of the hundreds of thousands of musculoskeletal disorders reported annually in the United States.

These injuries can result in significant pain, disability, and the associated financial stress of medical treatment and missed work for those afflicted. Employers are also taking a large brunt of the costs either outright or through workers’ compensation insurance, as well as dealing with a reduced workforce.

In a recent blog, we talked about the importance of having enough load capacity for your casters. Because when the load is not distributed properly, a breakdown can occur. Another problem is the increased push force due to a worn-out caster.

The amount of push-pull force exerted to start and continue rolling, as well as turn and maneuver, are ergonomic issues that can be reduced by utilizing the proper ergonomic industrial caster.

RELATED: TWERGO Achieves ROI in Less Than Three Months for Auto Manufacturer.

This happened at one American automotive manufacturer that had dollies moving loads up to 2,100 pounds. The push force required to move these dollies 24/7 was resulting in significant overexertion injuries, adding costs, and lowering productivity. By utilizing a 57 maintenance-free caster with an 8” TWERGO® Wheel, push force was reduced by 50%.

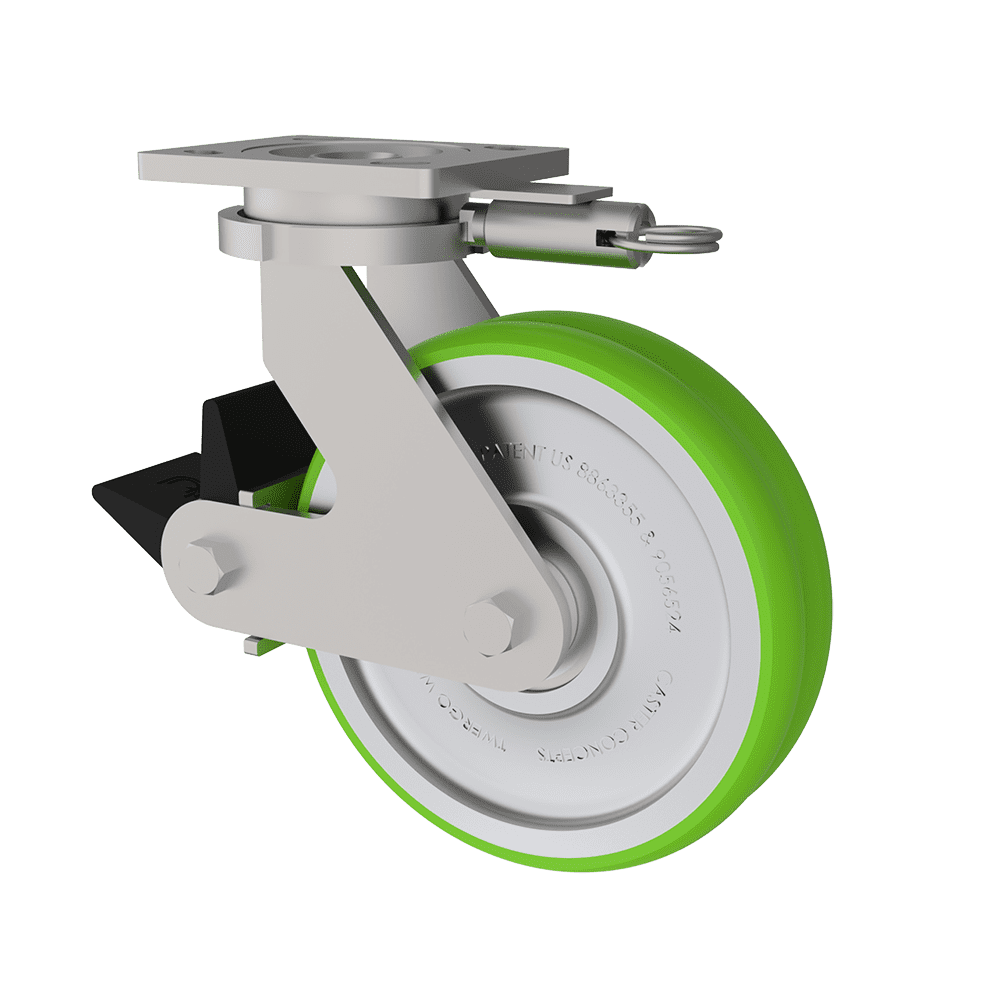

That’s why Caster Concepts offers a complete line of Ergonomic Wheels and Casters. When looking at efficiencies, many different aspects of the caster design affect the ease of moving a cart. The multiple-wheel design of our TWERGO® wheel allows for independent rotation of each component, while its unique tread thickness minimizes friction and eliminates scrubbing and sliding when turning. This ergonomic series includes the new TWERGO® XTREME, as well as our TWERGO®and TWERGO® Lite wheels.

Ergonomic Guidelines for Manual Material Handling also offers another way to reduce injury by implementing administrative improvements. They suggest observing how different workers perform the same tasks to determine ways to improve the process. Some of these ideas include:

|

Caster Concepts has a complete line of ergonomic wheels designed to require less force to turn, maneuver, and stop. These wheels help reduce the risk of injury for cart operators and reduce the amount of manpower required to safely move loads.