We often get questions from companies that are trying to move really heavy loads. Think 30K to 100K total load – that are concerned about what options they have with industrial heavy duty casters for uneven floors. Some applications are lucky in that they only move over smooth concrete or asphalt with limited to no obstructions. Yet there are many applications that are moving over uneven floors, expansion joints, railroad tracks, potholes, curbs, etc.

When moving really heavy loads, engineers typically run some sort of stress analysis to determine the worst-case conditions that the structure (and casters) may encounter. They try to reduce these stresses by adding features to their casters that help deal with uneven terrain. The most common options utilized in heavy duty casters for uneven floors are large, soft wheels, oscillating axles, and springs/shock absorbers.

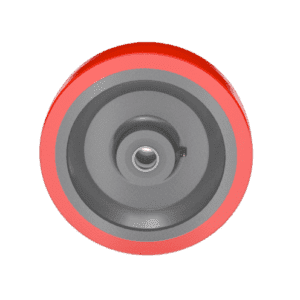

T/R 85 tread is industrial-strength with a softer touch.

The first option usually turned to is to try and utilize a wheel that is larger in diameter and has a softer tire material. This could be larger urethane tires with thicknesses of 2’’ or more or could be a large solid rubber wheel. The urethane holds more weight per size than rubber, so typically rubber is avoided unless traveling at high speeds.

The difference in sizes between two wheels that carry 17,000 pounds is significant. Rubber wheels will be approximately 33 inches in diameter, while urethane wheels can measure closer to 24 inches. Softer materials like rubber provide more deflection, allowing them to absorb some of the impacts when rolling over objects. Harder materials are going to impart more shock loading to the structure.

Oscillating axles are also popular options as casters for uneven floors conditions. These “floating” axles have a center pivot point that allows the wheels to oscillate a set amount of degrees from parallel. So if traveling on asphalt that isn’t totally smooth, this is a good option. If traveling over potholes, expansion joints, and other obstacles, the oscillating axle will not help absorb those impacts.

RELATED: Keeping your casters rolling: Four pitfalls to avoid.

Springs and other shock-absorbing caster systems are the best way to tackle bumps, potholes, and other obstacles with heavy-duty casters for uneven floors. These spring systems have been developed to provide shock absorption for loads of up to 100,000 pounds. Additionally, they can typically be customized to fit specific applications, including load capacity and wheel travel.

The spring systems are designed to achieve half deflection at the stated load. This design allows for travel upward to handle obstructions and downward to navigate holes, all while minimizing stress on the cart structure.

We design casters for uneven floors with three key features: large soft wheels, oscillating axles, and a shock absorption system.

This caster had to carry 30,000 pounds and was used in the aerospace industry to move a tool from outside the factory to inside.