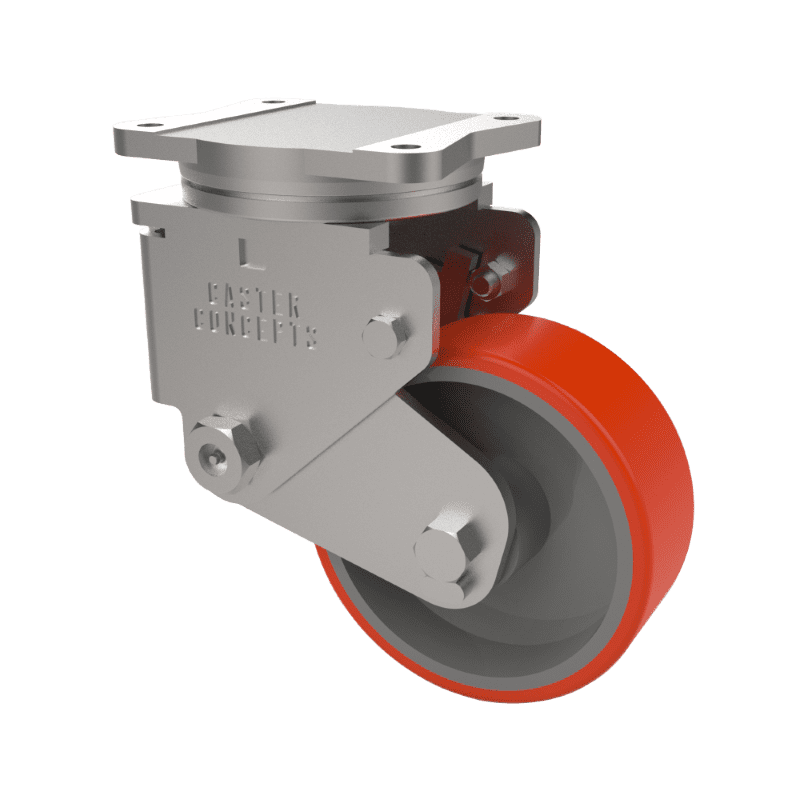

Spring-loaded casters are popular for applications when transporting heavy duty equipment or goods with minimal shock and vibration. However, when selecting spring-loaded casters for these applications, you must consider several factors to ensure that the casters provide stable and reliable support.

73 Spring Loaded Casters

One of the most important considerations when selecting spring-loaded casters for heavy-duty applications is the caster’s weight capacity of the caster. Before you consider protecting the load, your casters must handle the weight of the equipment or goods and any additional load weight applied during use.

The size and material of the caster wheels also need to be considered. Larger wheels can provide greater stability and better shock absorption, while softer materials like rubber or polyurethane can help to reduce vibration and protect delicate equipment. Harder materials like steel or nylon may be more suitable for heavier loads or rougher terrain. The type of wheel used will depend on the specific application and the conditions you expose the caster to.

Spring deflection is the response to a force applied or removed. For spring-loaded applications, you need to know how much the caster will deflect and under what loads. If you don’t know this information, your spring-loaded casters won’t perform as required.

RELATED: HOW DOES A SPRING-LOADED CASTER WORK?

Putting less load on the caster than it is rated for could mean little to no deflection happening because the springs are stronger than the load being applied. Or, if you put more load on than what the caster is rated for, you could overload the caster. In this case, when the caster hits a bump, there is no travel left in the caster to absorb the impact.

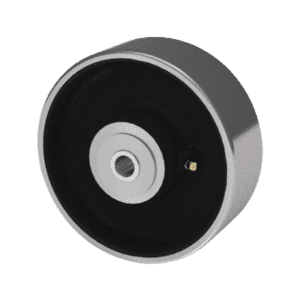

Forged steel wheel

Durability is another key consideration when selecting spring-loaded casters for heavy-duty applications. Heavy-duty applications can be demanding on casters, so it’s important to select casters that are constructed with durable materials and can withstand the wear and tear of regular use. High-quality materials like stainless steel or zinc-plated steel can help to ensure the longevity of the caster while also minimizing the risk of corrosion and damage.

It’s also important to work with a knowledgeable supplier who can help you choose the right casters for your specific needs. They can provide guidance on the weight capacity, wheel size and material, spring type, mounting options, and durability considerations. They can also provide recommendations on maintenance and cleaning procedures to ensure that the casters continue to operate effectively and safely over time.

In summary, spring-loaded casters can be an effective solution for heavy-duty applications where shock absorption and vibration reduction are required. However, selecting the right caster for the specific application requires careful consideration of several factors, including weight capacity, spring deflection, and durability. By understanding all considerations, it is possible to select a spring-loaded caster that can provide reliable and stable support, minimizing the risk of damage to the equipment or goods being transported.