I’m not trying to be funny or mysterious. Caster Concepts has an entire engineering team with a full array of test equipment — along with software packages for finite element analysis, allowing us to design a caster to fit any application. Along with all our design and testing capabilities, we manufacture everything right here in Albion, MI.

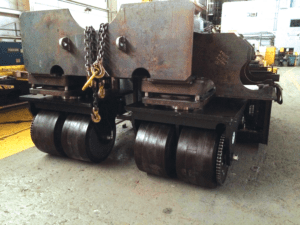

Our “standard” line of casters goes up to 50,000 pounds capacity. And really, you can customize these casters in many different ways to fit exactly within your application parameters. Here are some capability highlights:

Besides large casters with high-weight capacities, we have also done many specialized applications. Such as stainless steel ergonomic casters for vaccine carts and fully encapsulated high-capacity urethane wheels for marine applications. We’ve also developed super high-temperature casters for 900°+ environments, clean-room-safe motorized casters, and casters for all sorts of unique and challenging environments.

Where Caster Concepts does not tend to be a fit for customers is very lightweight applications. Typically, this would be for less demanding uses for casters under 800 pounds total.

Think about  toolboxes, Rubbermaid carts, shopping carts, etc. Mostly, those applications don’t have any particular performance requirements. So, as long as a caster is round and rolls, it will work.

toolboxes, Rubbermaid carts, shopping carts, etc. Mostly, those applications don’t have any particular performance requirements. So, as long as a caster is round and rolls, it will work.

These lighter-weight applications tend to be higher volume, so imported casters are usually found here. Once you start getting above 800 pounds of the total load to move, your caster choices depend much more on the factors of rollability and durability. Also, if an application is automated and runs continuously, usually a higher quality product is needed.

So, while we at Caster Concepts can cover any type of caster that you require, our sweet spot really is the heavier, more industrial, or specialized applications.