A common question received at Caster Concepts is “What is a Swivel on Swivel caster? And why would I use one?” This confusion is understandable because this technology isn’t widely used and has only been utilized in the last 20 years or so.

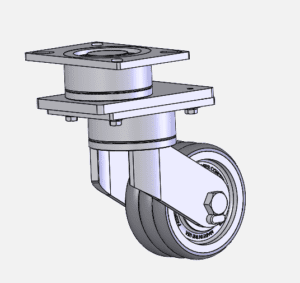

Swivel-on-Swivel Caster

To answer the first question, a swivel-on-swivel caster is a caster that uses two swivel sections that are offset from one another. So the caster ends up with two swivel offsets. First from the centerline of the top swivel section to the lower swivel section, and second from the lower swivel section to the middle of the wheel. The dual offset swivel section gives the caster two degrees of freedom when swiveling/rotating.

| Manually Pushed Operations: Swivel-on-swivel casters excel in situations where the caster needs to make precise 90-degree turns during movement. This can be challenging for push-pull forces, but swivel on swivel casters help by generating momentum before the swivel wheel starts to move. | AGV Applications: Automated Guided Vehicles (AGVs) often follow repetitive routes. Swivel-on-swivel casters are excellent in AGV applications because they help AGVs stay on track without deviating from their intended path. This minimizes the castering effect and ensures the vehicle’s precise movement. |

If you have a manually moved application, there are more limited uses for swivel on swivel casters. From an ergonomics standpoint, it can help in applications where the casters are pointed at 90° from the direction of movement. A good example is line drop-off situations where the casters on a parallel-parked cart are pointing 90° to the next direction of travel.

This position requires the most amount of force to get the cart moving because you have to make the casters start to swivel before the wheels begin to roll. The dual swivel sections with the second degree of freedom allow you to build some more momentum with the cart. This then helps the lower swivel section move, and hence the swivel wheels begin to rotate.

We have seen push forces reduced by up to 40% in these types of applications. In a typical application where a caster is just moving forward and then rotating to move backward, the swivel-on-swivel design has few ergonomic benefits compared to a single swivel caster.

AGV Casters with Poly Toe Guard

Swivel-on-swivel technology is used in powered applications, especially automated guided vehicles (AGVs). This is because many powered applications use drive swivel wheels and then swivel casters on the corners as load support. When using more than two swivel casters on a vehicle, the swivel on swivel technology can dramatically affect the vehicle’s performance.

The first application of improved performance occurs when the vehicle has to stop and move directly 180° in the opposite direction. When this happens, the swivel casters have to rotate, which tries to move the vehicle offline. So, you either need powerful enough motors to push through the force of all casters swiveling at once or have enough clearance to move offline.

The swivel on swivel technology, with the second degree of swivel freedom, reduces the castering effect so not all of the swivel casters are trying to rotate at the same time. This reduces the amount of power required from the drive system and does not require additional programming or sensors to accommodate the vehicle moving offline from its original path.

The second application of improved performance occurs when the vehicle has to stop and move directly 90° to the previous direction of travel. Moving assembly lines use this type of maneuver with benefits similar to what was described above.

In a typical single swivel caster design, the vehicle moves out slightly and makes a slight arc when moving 90° due to the castering effect. This can move the vehicle closer to whatever object may be in front of it. By utilizing swivel on swivel casters, the castering effect is minimized, so the position of the vehicle is more tightly controlled.

In conclusion, swivel-on-swivel caster technology has been around for a few decades but is only used in specialized applications. The major benefit is on powered applications, as it can help improve push forces in certain manually operated applications.