A question that many customers have is, “What bearing is in my caster wheel?” In my experience, this question typically comes up when a customer is looking for replacement parts. They want to rebuild a good industrial wheel that is currently in use, but the component parts on the inside of the wheel have worn out.

All things wear out over time, but there are ways to lessen the impact. Performing proper maintenance such as regularly scheduled greasings will help to prolong the life of your bearings and reduce replacement costs. And when the inevitable does happen, knowing the part number of the caster that needs replacement bearings helps us to quickly identify what type of bearings are needed. However, there are a lot of times when the customer comes to us for help but they do not have the part number handy.

That’s ok! There are a few ways we can determine what kind of bearing is inside a wheel. Viewing the wheel, even if it’s just an image, is one way. Or, checking whether it spins freely or with some resistance can also be telltale signs of what bearing is being used.

For starters, if there is a grease fitting, or what we refer to as a “Zerk” on the axle of the wheel, this means that the bearing is a straight roller bearing. Straight roller bearings come pre-greased but are not maintenance free. They need to be greased over time. The advantage of these bearings is that they can carry a greater load than a same-size diameter ball bearing.

The straight roller bearing assembly is cylinder shaped with rollers going all the way around. This cylinder roller assembly is then inserted inside a metal sleeve. The sleeve has a split running down its side and acts as an outer race shell. At each end of the shell, a hardened washer keeps the bearing in place inside the wheel.

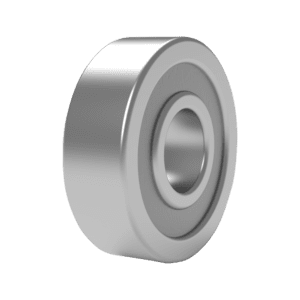

Precision sealed ball bearing

The next bearing we will discuss is a precision ball bearing. These bearings are recommended for maximum rolling ease and quiet operation in medium-duty to heavy-duty loads. Although we call it a ball bearing, it really is in the shape of a ring. And unlike a wheel with a roller bearing, a wheel containing a precision ball bearing doesn’t require a Zerk fitting. The reason it doesn’t have a Zerk fitting is that no lubrication maintenance is required. The other test to determine a precision ball bearing is to spin the wheel within its caster rig to see if it spins freely.

The final bearing to review is a precision tapered bearing. Like the ball bearing, you can test for a tapered bearing by spinning the wheel inside its caster rig. In this case, we are looking to see if the wheel spins with some resistance. If so, it is likely that the bearing inside the wheel is a tapered bearing.

Like the straight roller bearing, a tapered bearing will need some maintenance and adjustment to prolong bearing life and also comes with a zerk fitting for periodic greasing. This is done by inspecting the two components of each tapered bearing. One is the cup on side of the tapered bearing. The other is the cone on the other side that fits into the cup to form the complete tapered bearing. Precision tapered bearings are the most effective bearings for heavy loads, and are capable of absorbing excessive side thrust loading and can be used where higher speed operation is necessary.