In many different sectors of manufacturing, debris is everywhere. And in many forms. Including the dust, dirt, and other debris from employee foot traffic. Or, air particles that find their way to the floor and the bolts and metal shavings left over from the assembly process.

Which brings us to the main challenge: How do I prevent debris from affecting our Caster?

The solution that works best for you depends on what type of debris you are dealing with. Certain polyurethane types, the shape of the caster wheel and other protective measures can all help you in your quest to keep debris from making your life difficult, whether it’s shortening caster life or making the casters harder to move.

When it comes to what material to use, you need to ask yourself, “What is the most important thing I want out of these Casters?” There are pros and cons to any material, so lets take a look at the options.

If you want to eliminate the wheel picking up debris altogether, go to a steel wheel. The downside of using a steel wheel however, is how much it may damage your floor.

This is where Phenolic and Nylon wheels come into play. Both these types of wheel material are softer than steel and roll easy, so your floors stay nice and you stay happy. The challenge relates to the plastic aspects of these wheel materials. When phenolic wheels come into contact with debris, it can cause chunks to come off the wheel and fall apart. And with soft polyurethanes, they are great for keeping a floor nice and crack free, but they also pickup debris more that just about any other material.

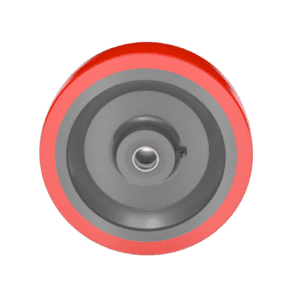

Designed to roll easily and quietly, the T/R 85 tread is ideal for applications that require the industrial-strength, with a softer touch

We recommend using a polyurethane within the 85-95A durometer range as the best choice for debris prevention. These polyurethanes have great rebound (ability to roll out a dent from debris) while also being tough and tear resistant. And, of course, they are easy on floors.

When choosing a wheel shape, it really comes down to this:

The more wheel contact on the ground, the more debris gets picked up.

It honestly is that simple (with this category let’s not get too carried away). That’s why tapered wheels are also a good way to go, as they present less surface area.

There are additional options to eliminate debris pickup on wheels and casters, such as adding a track brush wiper to your casters. In most cases, these are made out of nylon brushes that run against the wheels to knock off debris as the casters are rolling. Using a polyurethane wedge can have the same effect. We make these to be mounted on either your wheel or in front of your wheel to push debris out of the way as the application is being used.

Another thing we can do is add a toe guard with a Polyurethane or Nylon brush bottom border. This has the same effect as a track brush wiper while getting the added benefits of the toe guard to protect your workforce from getting their toes ran over.

Just keep in mind that adding these features can effect your push/pull numbers due to the resistance the brushes put on the wheels.

When it comes to sand, dust, and other fine particles, you want to seal up the bearings in both the wheel itself and the caster swivel section as quickly as possible. Caster Concept’s line of maintenance free casters are sealed at both the swivel section and the wheel core, mitigating all fine particle debris from getting in and ‘gunking’ up your casters.

Using a sealed caster in combination with a track brush wiper or a brushed toe guard will give you ultimate debris resistance. Click here to learn more about our Maintenance Free line of casters.

In terms of nuts, bolts, and larger/heavier debris, the track brush wiper or brushed toe guard will be your best friend. The way these parts function, any piece of debris that falls into this category will virtually never come in contact with your wheels.

In terms of nuts, bolts, and larger/heavier debris, the track brush wiper or brushed toe guard will be your best friend. The way these parts function, any piece of debris that falls into this category will virtually never come in contact with your wheels.

Keep in mind, however, that whenever resistance (wiper or brushed guard) is applied to something that rolls, it makes it harder to move. If you are already close to not passing internal safety standards, some of the other options we talk about in this blog may be a better solution.

In this situation, you need to decide whether caster or floor longevity is more important to you. Sharp debris can be a polyurethane wheel’s mortal enemy, as the compound of poly can be sliced easy. But on the flip side, steel wheels and concrete floors have hated each other as long as they have been in contact with each other. Track brush wipers and brushed toe guards can be very helpful in these situations, but the one or two percent of material that the brush doesn’t catch will effect your polyurethane wheels. Make sure you consult a representative if you find yourself in this situation and we can work with our engineers to get the best solution!