Following up with the second portion of caster terminology, Part 2 will talk about the wheel and its associated terms.

Wheels can come one of 2 ways. The first is a standard wheel, which needs maintenance. The second type of wheel is maintenance free. This is an important distinction because casters that require maintenance will come with a zerk. The zerk is located on the hub of your wheel right next to the bore where the axle runs through the middle of the wheel.

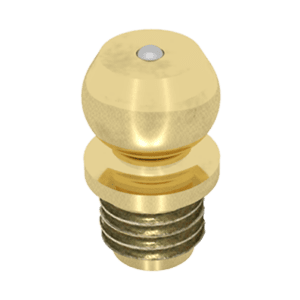

zerk fitting

A zerk is a grease fitting that allows you to add grease as needed to maintain your bearings so they won’t become rusted — or, in some cases — ruined due to high-temperature applications such as ovens. In the case of oven applications, greases are made to withstand varying high temp applications for extended periods. These can sometimes be as high as 1,000 degrees.

On a maintenance-free caster, the zerk will not be present because the bearings will be sealed with grease already inside. If the zerk isn’t present on your wheel, it is a good way to tell that your wheels most likely have a precision ball bearing inside.

Caster wheels can come in many different shapes due to having different faces or contact surfaces with the rolling surface. These may be a crowned face, a flat face, or even what we refer to as a balloon tread. These all have their niche in the caster industry.

A balloon tread will improve ergonomics by having less of the wheel face contacting the floor. The area of contact between the wheel and the floor is also called the “footprint” of a caster or wheel. A wheel with a flat face will be better for heavier load capacity because the weight is dispersed over a larger footprint, which covers a larger area on the floor.

Two other wheel styles I want to focus on are V-groove and U-groove. These will either be cast iron or forged steel, depending on the load capacity needed and your application’s use.

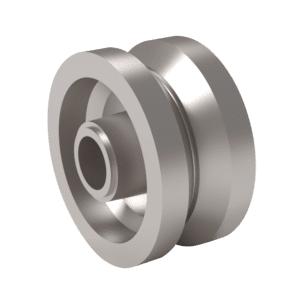

V-groove wheel

A V-groove will have a V cut in the middle of the face of the wheel. This will allow the wheel to do one of 2 things. Either ride on a rail within that V or let the wheel ride on the floor using the rail as a guide in the middle of the V.

Drive or Keyway Wheel

A U-groove will typically run on some pipe, allowing the wheel to curve around the pipe’s outer surface. In both cases, it is essential to have exact dimensions for the V or U-groove to ensure the wheel fits as needed.

Another wheel that needs exact measurements is a Keyway wheel. The Keyway of a wheel is a rectangular notch that gets cut out of the bore where the axle runs through the wheel’s center. These wheels will typically be used in applications as a drive wheels for conveyors.

For a more in-depth take on these specific terms and topics, please look for their related videos or blogs on our website and YouTube. Our website Learning Center is also a source to help educate on further caster info.