I often find myself on the phone with a customer trying to explain our part numbers. So, I want to teach you how to decipher our part numbers and show everyone that even you could become a part number expert! And if you are having trouble finding your part number on our site, be sure to check out Three common reasons why you can’t find your part number on our website.

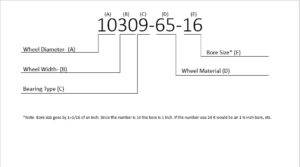

For this wheel number blog, we will use Part Number 10309-65-16 as our example. Let’s break down each section.

For this wheel number blog, we will use Part Number 10309-65-16 as our example. Let’s break down each section.

Exhibit-A: 10 These first two numbers represent the diameter of the wheel. We have sizes ranging from a few inches to a couple of feet. The diameter of the wheel is dependent on the application. If you are running with an application that’s maxing out at thousands of pounds, it would be in your best interest to go at a larger diameter. Of course, not every application has the liberty of picking wheel diameter, so we can make wheels of all different sizes. (note, if wheel diameter is a single-digit number, you must include a zero in front. For example, an 8-inch diameter would show as 08).

Exhibit-B – 30 In this numerical position, you will find our wheel width. Wheel widths can vary greatly, and the most variation you will see is between the lighter and heavier applications. You’re more likely to see wider wheels or dual wheels in large applications usually dealing with serious tonnage. Wheel width and diameter go hand and hand in terms of manufacturing. We are capable of producing virtually any size wheel possible for your application.

Exhibit-C: 9 This number represents the type of bearing used. We offer many different types of ball bearings, determined by your application. Heavier applications tend to use the precision tapered bearing due to its resistance to high weight capacities, but retrofitting these bearings to medium and light applications is doable. Other common bearings that we offer are precision ball bearings and roller bearings, although we do offer other types.

Exhibit-D: 65 These two numbers represent the wheel material. Here at Caster Concepts, we offer over 40 different wheel materials, including different hardness varieties in polyurethane, steel, and iron, along with variations of rubber molds. Wheel material is entirely dependent on location and application. If you’re looking to improve ergonomics, try looking at our Twergo line of casters. If you want an extremely durable wheel, look no further than any variation of our steel wheels. Are you trying to keep your floor intact? We have solutions for that as well.

Exhibit-E: 16 This is where you can find the Wheel/Bearing Bore size. Our system works like this; 1= 1/16 of an inch. So, if your wheel/bearing bore was 1 inch, it would show as 16 on the part number. If your bore was an inch and a half, your bore would be 24 numerically in the part number.

Here at Caster Concepts, we work closely with manufacturers and end-users to ensure we’ve accounted for everything, from load capacities to safety factors and everything in between. Caster Concepts works hard to ensure that the Caster or Wheel made for you is a tailored fit.